Nowadays, more and more charcoal briquette manufacturers are prone to turn sawdust into biochar briquette. And there are already professional charcoal briquette production lines in the market. But, the design of sawdust charcoal briquette production system usually varies with capacity. This will lead to changes in area occupation, cost, labor, etc. So before buying sawdust charcoal briquette production plant, we recommend you clear your output. Then how about a 3 t/h sawdust biochar briquette production line? On 5th March 2024, a customer from India inquired about this.

What is the design of a 3t/h sawdust charcoal briquette production plant?

The client from India told us that the raw material will be local sawdust, and the sawdust biochar briquette processing line capacity is 3 tons per hour. And he wanted to know which sawdust charcoal molding system is the most suitable one? And what is its design?

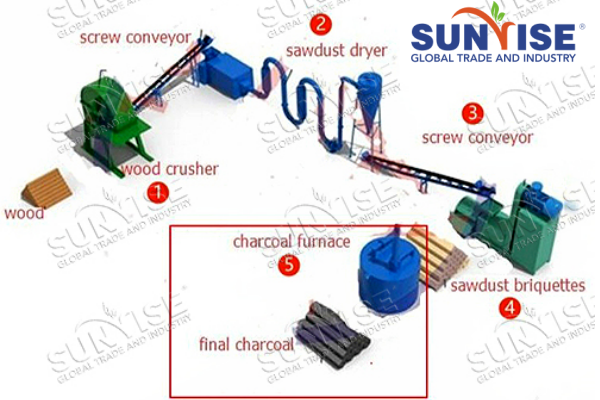

If you want to produce 3 tons of sawdust charcoal briquette per hour, we recommend you choose our charcoal extruder briquette line. Because it is an ideal choice for large scale sawdust biochar briquette making. There are two reasons. For one thing, it makes sawdust into sticks, which is more convenient to transport, store and use. For another it has characteristics of low cost, less area occupation, over 99% briquetting rate, etc.

What is the design of 3 t/h rod charcoal briquette plant for sawdust disposal?

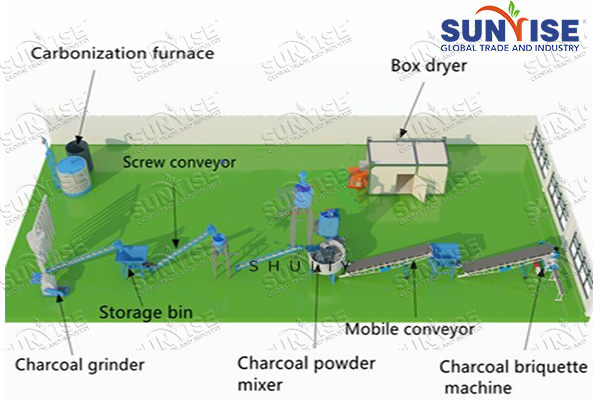

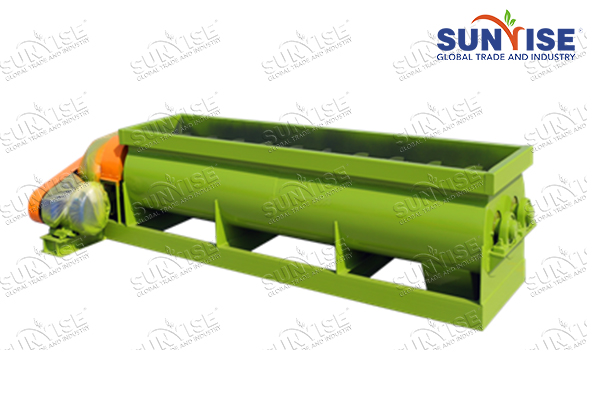

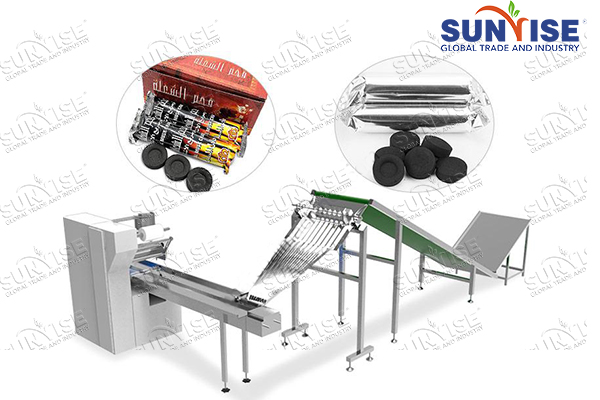

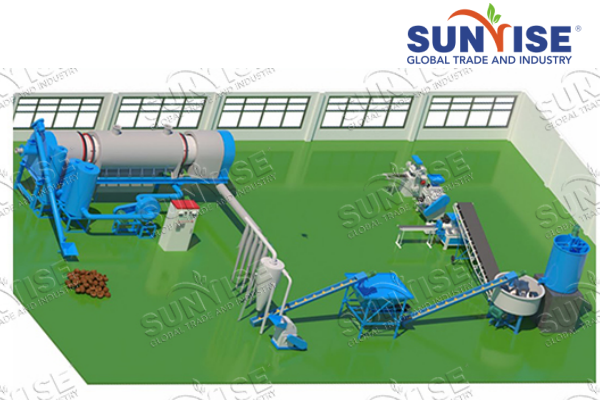

In general, a complete large scale rod charcoal briquette making line usually consist of hammer mill, double shafts mixer, YSHG-1010 rotary dryer, YS-180 rod extruder, YS-20 horizontal carbonization machine, automatic packaging machine and belt conveyor.

How much area does the sawdust rod charcoal briquette plant cover?

After knowing the design, the Indian’s customer paid attention to the space requirement of sawdust biochar briquette manufacturing. He wanted to know can the workshop accommodate the 3 t/h sawdust charcoal briquette production line? Generally, a whole set of charcoal extruder briquette line equipment needs an area of 800-1,500㎡.

How to start 3 t/h sawdust biochar briquette making in a smaller space?

On the one hand, you can replace equipment with a smaller area occupation. For example, you can use hoisting carbonization furnace in sawdust sticks carbonization, which only needs a 9-16 ㎡area. On the other hand, you can provide us with more details of your sawdust biochar briquette making plant area. We will offer you a customized charcoal briquette making business plan, which will make full use of the surrounding land.

How much does a 3 t/h sawdust charcoal molding system cost?

Generally, you need to prepare $50,000 – $300,000 for the above 3 t/h charcoal extruder briquette plant. However, if you want to finish sawdust charcoal briquette making at a lower cost, we can also meet your requirements.

You can reduce the cost by only turning sawdust charcoal into briquette. Because it only needs load type feeder, crusher, mixer, rod charcoal briquette machine, bagging equipment and conveyor. The fewer the fertilizer machines, the lower the cost. You only need to choose sawdust charcoal as materials. This solution is a reference, you can choose materials according to your local condition.

Labour and skills required to operate this sawdust charcoal briquette plant

Moreover, the customer from India asked us about labour and skills required to operate about this sawdust biochar briquette manufacturing system. Don’t worry, our rod charcoal briquette making line has a high degree of automation. In general, only needs 3-5 workers, it can finish the whole process of making sawdust into quality charcoal briquette.