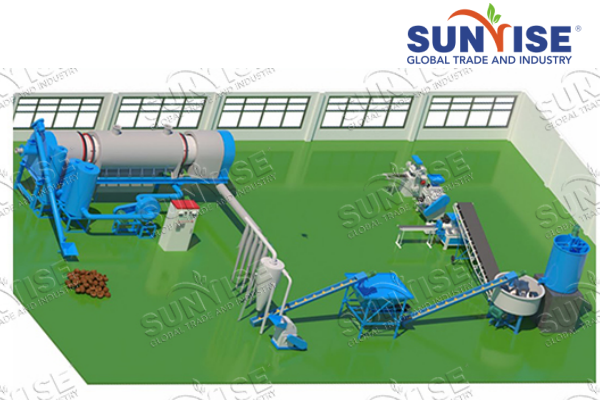

In South Africa, there are abundant raw materials that can be processed into economical product. But how to dispose of materials to get more profits? For this, a customer from South Africa chooses to turn them into charcoal briquettes. But how to manufacture charcoal briquettes? On 10th January 2024, the South African client inquired about the project for making biochar pellets. After considering the actual conditions and requirements from the customer, we design a 1 t/h charcoal briquette production line as follows:

What raw materials are suitable for manufacturing charcoal briquette?

How to reduce moisture content of materials to make high quality charcoal briquette?

What is the application of biochar briquette in South Africa?

This South African customer prepares to use sugar cane, corn stalks, rice husk and wheat straw, etc as biomass materials. These materials are suitable for making biochar briquettes. Why do you choose to turn these materials into biochar briquettes? In general, charcoal briquette has a variety of uses in South Africa, including agriculture, energy, water and livestock.

South Africa has a very small proportion of arable land. Biochar briquette can be used to increase the nutrient and water storage capacity of soil.

Barbeque (Braai) is a traditional food in South Africa. Charcoal pellets are suitable for using as fuel for barbecues. And South Africa relies on coal-fired power generation. So using charcoal as fuel for factories can appropriately alleviate local energy shortages.

The activated carbon is a good material for removing odors and impurities from water.

In South Africa, there are a large number of farms. You can add biochar briquettes to feed to improve animal digestibility. And charcoal briquette can be used to absorb gases emitted by animals. This helps reduce greenhouse gas and ammonia emissions. Then adding an appropriate amount of biochar pellets to the animal manure mat will help reduce odor and drain water. This contributes to the animal’s health.

How to make charcoal from biomass materials in South Africa?

After understanding the uses of charcoal briquette, the customer from South Africa clearly decided to produce biochar pellets. Before producing charcoal briquettes, you need to carbonize the material. What charcoal kiln is suitable for you?

Suitable capacity

This client could collect 50 tons of biomass materials for biochar making. Because the general carbonization rate is 30%, it needs charcoal making equipment with an output of 1 t/h. Here,YS-1912 rotary charcoal kiln can make 900-1100 kg of charcoal from biomass materials per hour. So it can fully meet the large scale biochar making of 1 t/h.

Carbonizing biomass materials quickly

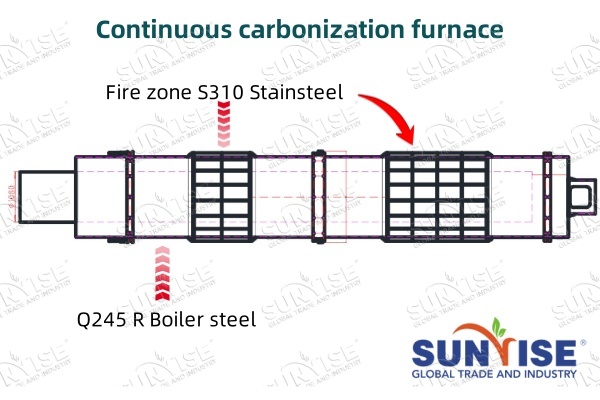

Our continuous carbonization furnace has characteristics of PLC control system, indirect-fired method, Q245 R steel + 310S stainless steel materials use, etc. So during the pyrolysis of biomass, the temperature inside the rotary drum can reach 550°C-650°C. In this way, you complete the biomass waste within 30 min.

Making biochar environmentally and friendly

In addition, YS-1612 rotary kiln also can help you make charcoal with a low energy consumption and no smoke. There is a gas dust treatment system designed for it. The system can purify combustible gas from carbonization. Then you can use the purified gas as a heat source for subsequent process of tea cuttings to biochar.

What other carbonization machines can make biomass charcoal?

Besides continuous carbonization furnace, hoisting carbonization machine and batch type carbonization machine can also make 1 t/h biomass charcoal. But you need to turn biomass materials into rod shape briquettes firstly. Because their feed requirements are rod-shaped materials. So charcoal extruder machine is necessary. For this, how does hoisting carbonization machine and batch type carbonization machine make biomass charcoal?

Hoisting carbonization machine

With the electric hoist, it can lift the inner tank easily, which save labor cost. And each furnace is equipped with 3 inner tanks. Then its carbonizing time is 8-12 hours to ensure the good quality of charcoal. After one tank of materials finishes carbonization, you can lift out it by the hoist and then put another tank of materials for charring.

Horizontal carbonization furnace

It produces charcoal by batch. And its carbonizing time 8-10 hours, water cooling time 2-3 hours and air cooling 6-8 hours. What’s more, its furnace body has three layers. The inner layer is high heat transfer and wear-resistance steel for increasing the carbonizing temperature. The outer layer is painted steel. The middle layer is the Aluminum silicate fiber insulation. Finally, the door of the furnace is sealed with ceramic packing.

What is the requirement of charcoal for making briquettes?

This customer from South Africa wanted to know the requirement of charcoal. There are three requirements of charcoal for making high quality briquettes. Size, moisture and binder. You need to adjust charcoal according to these requirements.

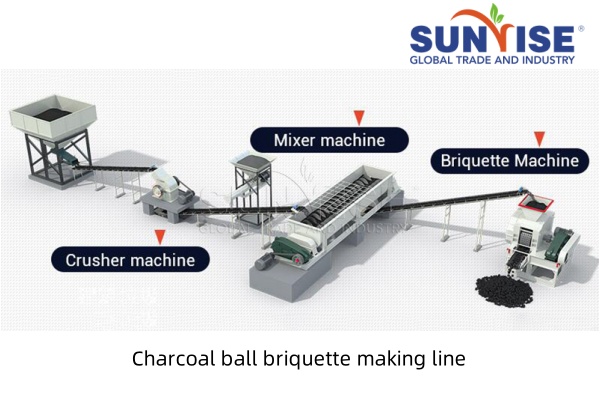

The charcoal size should be less than 5mm so that you can easily press them into briquettes. For some large-sized charcoal such as lump charcoal, coconut shell charcoal, etc., it is necessary to use a charcoal crusher to crush it into powder before proceeding to the next step of mixing.

The moisture of charcoal for making briquettes is around 30%. So proper moisture is good for the briquettes forming and increasing the density of the charcoal briquettes.

Usually, the binder is necessary for the charcoal briquettes processing. Because binder can make the charcoal briquettes more solid and smooth. And the most common binder is corn starch or cassava starch. The best binder adding rate is 4%-6%. There are also some customers who add the combustion improver to accelerate the lighting speed of charcoal. No matter binder or ignite accelerating agent, you can use a charcoal mixer to blend the charcoal powder with water and additive evenly.

Top 3 charcoal briquette making machines for your choice

This South African client prepared to select a suitable biochar briquette machine. So we introduce 4 charcoal briquette machines for his choice.

The roller briquette press machine makes a continuous charcoal briquette process with large capacity. With one briquetter, the capacity can even to 35 t/h. And the briquette is also easy to be packed with packing machines. So it is the most popular in the industry.

Extrusion briquette maker is an ideal briquette machine for charcoal briquette making in industry. The shape of the briquette is much different from the roller briquette presses, the briquette is made with low energy cost. And it usually adopts two charcoal briquette making methods.

Shisha charcoal briquette machine adopts a double-pressing design. It consists of a set of molds arranged in a tray. When the machine is working, the mold rotates and compresses the charcoal powder into a tablet or cube shape.

Which one is more profitable between charcoal briquettes and biomass pellets?

Finally, Charcoal briquettes and biomass pellets are all biomass fuels that is now very hot business project around the world. Many people who are interested in or want to invest in biomass industry are wondering which one can make much more money? Actually, the two biofuels have many commons as well as many differences.

They are both made from sawdust wood residue and other agricultural and forestry waste, and they are both used as fuels for civil and industrial industry. However, if you are going to start charcoal briquette manufacturing business or biomass pellet production plant, you should clearly know that biomass pellets and charcoal briquettes are targeted at different customers.

Therefore, before starting it, it is very important to find the right customers for your charcoal briquetting factory or pelletizing plant. Because of different demands, the profitability of biomass pellet and charcoal briquettes could not be completely compared. However, as long as adopting scientific management and finding out the accurate customers, you will be successful and gain profits from your own biomass pellets or charcoal briquettes manufacturing business.

Six Recipes for Making Charcoal Briquettes

What is the design of $100,000-$300,000 cost charcoal briquette plant?

This customer form South Africa prepare to use $100,000-$300,000 to finish charcoal briquette manufacturing. Then for the $100,000-$300,000 budget, we recommend you the following two charcoal briquette manufacturing lines, which are popular with charcoal briquettes suppliers.

500 kg/h charcoal briquette manufacturing investment

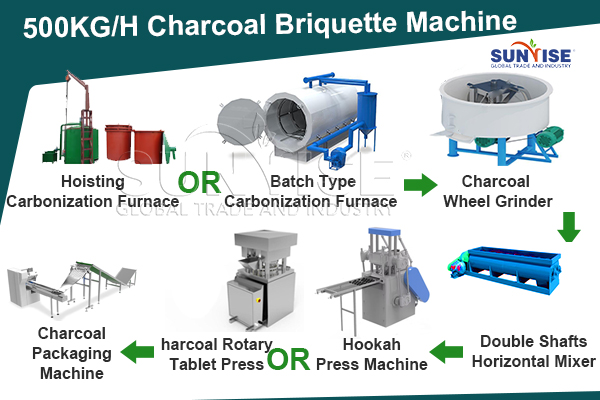

As for charcoal briquette making with $100,000-$300,000, you can buy our 500 kg/h hookah press line. It includes hydraulic and mechanical method. So its briquetting rate can reach over 95%. After carbonization, crushing, mixing and charcoal briquette making, you also need to use dryer to remove excessive moisture from produced charcoal briquettes. Finally, packaging biochar briquettes into bags.

1000 kg/h biochar briquette making budget

With $150,000-$300,000 budget, you can enlarge the biochar briquette production line scale to 1000 kg/h. Correspondingly, the charcoal forming equipment in this production line will be upgraded. It employs batch type carbonization machine, charcoal wheel grinder, double shafts mixer, charcoal extruder, mesh belt dryer and automatic packaging scale. They have a large capacity and can help you produce charcoal briquettes more quickly.

4 Main factors affect the cost of charcoal briquette plant

Finally, according to the above budget, this South African customer wanted to know where else to spend money besides buying equipment. In general, for charcoal briquette plant cost, we mainly consider it from 4 aspects. Including material, equipment, running and area.

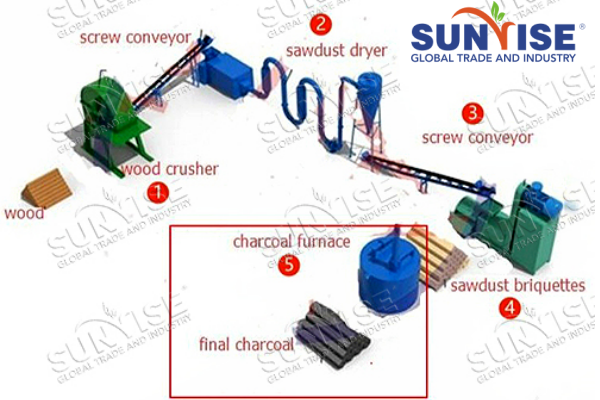

The above are details about our communication with the customer about how to manufacture charcoal briquettes in South Africa. In addition, we can also provide you with many other charcoal molding projects. Such as sawdust biochar briquette making or wood to charcoal, coconut shell to shisha charcoal, etc.