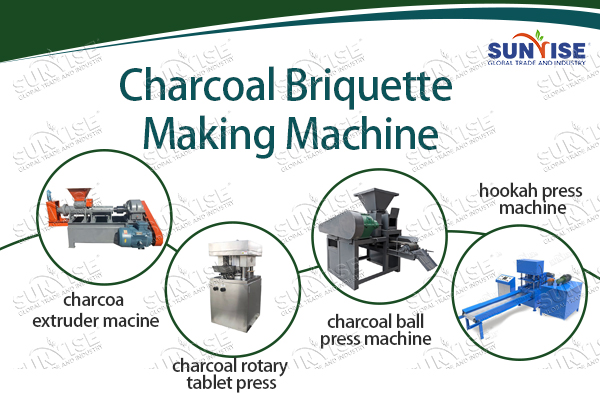

There are two charcoal briquete making method for your choice. Forming first, then carbonization and carbonization first, then forming. In this way, you can select a suitable method according to your requirement. Because the charcoal briquette making methods are different, the equipment used is also different. Therefore, as a professional charcoal briquette making machine manufacturer, Sunrise designs types of machines to meet customer’s needs. You can produce biochar briquette with them easily.

Hot selling charcoal briquette machines about forming first & then carbonization method

According to the current investigation into customer’s needs, our engineers design four types of charcoal briquette machines for this method. At present, they have won good feedback from countless customers. There is some information about them shown as follows:

Crushing machine

When your materials are wood, bamboo, coconut shell and wood shaving, etc, but you also want to use forming first & then carbonization method. Crusher is necessary. We recommend you with hammer mill. It can grind materials into 2-5 mm. If you want to make finer powder, Raymond mill can also help you after using hammer mill. And it can make powder material into 80-800 mesh.

Rotary drum dryer

If your materials are wood or sawdust, they will have some moisture. It can influence the briquette production. For this, rotary drum dryer is the best choice for you. It can reduce the moisture below 10-15%.

Rod making machine

Because of forming first & then carbonization, you only use rod making machine to make briquettes. This machine make briquettes through using extrusion configuration. And it can produce 1-10 t/h briquettes. Furthermore, you can also replace mould to adjust the shape of briquettes.

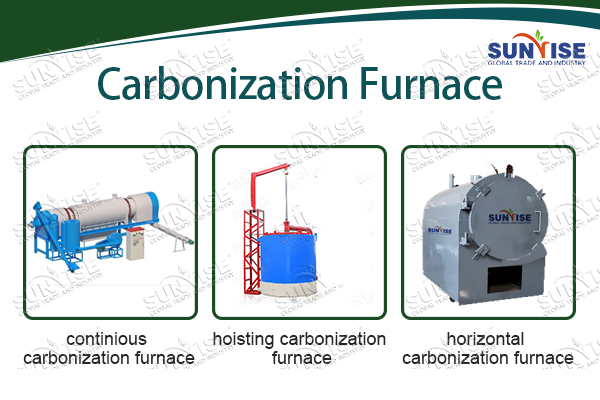

Carbonization machine

Finally, you can use carbonization furnace to make charcoal. Because rod making machine produce rod-shaped briquettes, there are only two carbonization furnaces for your choice. Hoisting carbonization machine and batch type carbonization furnace. They both can be suitable for rod-shaped briquettes.

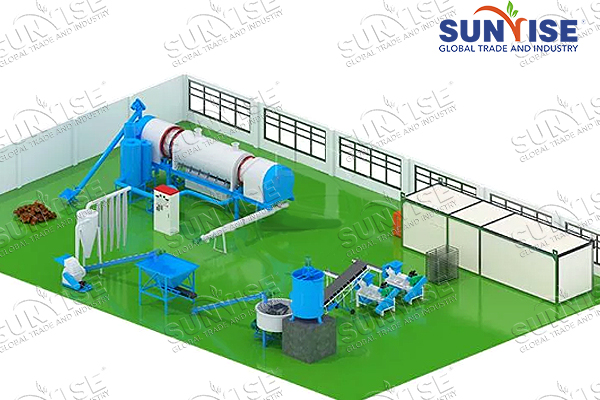

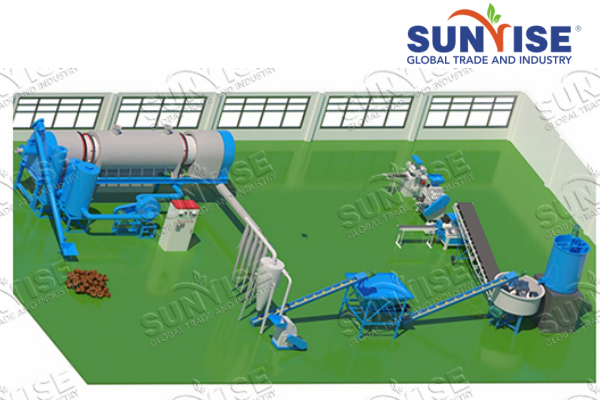

What equipment is used for carbonization first & then forming method?

Compared with forming first & then carbonization method, there are more types of machines for carbonization first & then forming method we can provide you. Some basic information about them showed for you is as follows:

Why forming first & then carbonization method is favoured than other method?

As mentioned above, both forming first & then carbonization and carbonization first & then forming are good charcoal briquette making methods in biochar briquette preparation. According to statistics, in the process of charcoal briquette production, a large part of charcoal briquette producers like to use forming first & then carbonization method, so why can this method attract them?

Why choose us from so many charcoal briquette making machine manufacturer?

In addition to determining the type of machine you need, it is also important to choose a reliable company. Henan Sunrise Biochar Machine Co., Ltd. is absolutely an excellent choice for you because we can provide you with the best service.

As a professional charcoal briquette equipment manufacturer, our company will provide you with high quality charcoal briquette making machines at the best price. Whether you want to build a new biochar briquette production line or upgrade an old one, whether you want to start a bamboo charcoal briquette plant or BBQ biochar briquette factory, you can contact us for consultation.