In 2024, the demand for sustainable and eco-friendly fuel sources continues to rise, leading to an increased interest in charcoal briquette production. So there are so many people investing in charcoal briquette production lines. From the selling data in the past ten months in 2023, we find there are 3 types of charcoal briquette plants that are hot selling with charcoal briquette suppliers.

NO.1 Sawdust charcoal briquette making machine

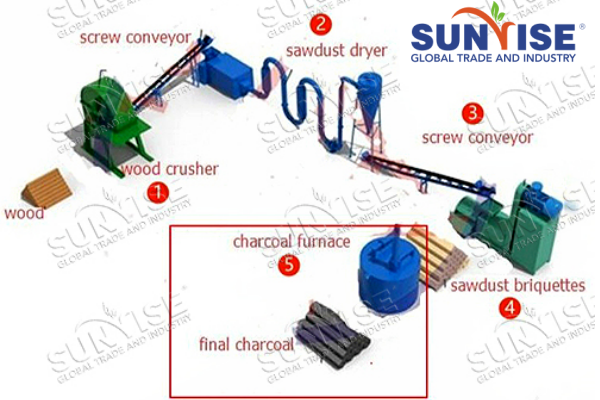

Sawdust charcoal briquette making machine transforms sawdust into high-quality charcoal briquette through carbonization technology. This offers an effective solution for waste disposal in the wood processing industry. This sawdust charcoal briquette has extensive applications in industry, agriculture, and other fields, presenting lucrative prospects for investors. YUSHUNXIN offers comprehensive sawdust to charcoal briquette recycling solution, ensuring utmost convenience for your investment.

Why so many customer choose sawdust as material to make charcoal briquettes?

Sawdust is the foam-like particles generated through woodworking operations in sawmills, pulp mills, etc. While sawdust is typically seen as industrial waste in the timber sector, some of its characteristics make it ideal for the production of valuable charcoal briquette.

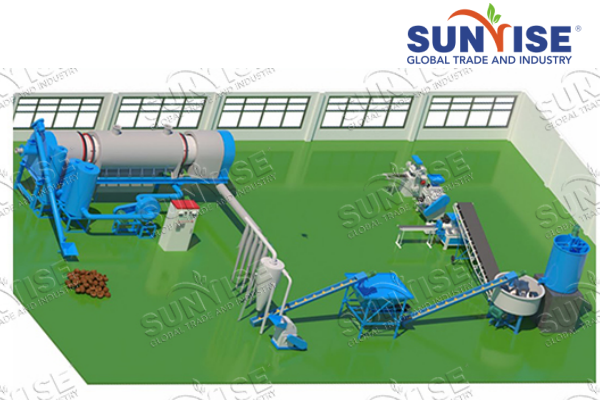

What equipment is suitable for making sawdust biochar briquettes?

NO.2 Bamboo charcoal briquette plant

YUSHUNXIN bamboo charcoal briquette plant can produce charcoal briquette from bamboo. Similar to wood charcoal briquette and coconut shell charcoal briquette, bamboo biochar briquette plays important roles in many aspects of human activities and has a high market value. Therefore, if there is plenty of bamboo in your place and you want to make money from them, you can choose our bamboo charcoal briquette machine. It will be an investment with a high ROI (rate of interest).

What is the usage of bamboo charcoal briquettes? – Bring good economic profit

Bamboo charcoal briquette is not activated carbon. It is a kind of carbon-rich thing. Through high-temperature carbonization and charcoal forming, the bamboo will be converted into charcoal briquette. See its wide applications.

Heating Fuel & BBQ & Hookah

Bamboo charcoal briquette has a fixed carbon content of over 80%, making its calorific value about 30% higher than wood charcoal briquette. Therefore, it suits to be used as fuel in cement plants, power factory, brick plants, etc and used for BBQ or Hookah.

Poultry Field

- Act as animal feed additives to improve animals’ digestion and health;

- Function in stockyard bedding to absorb odors and improve the environment;

- Absorb ammonia emitted by animals and their excrement.

Soil Improvement

- Bamboo biochar briquette is a good material to improve soil quality. It can:

- improve soil aeration and drainage and enhance soil structure;

- increase nutrient retention and promote plants’ healthier growth and higher yields.

- regulate soil pH, etc.

Metallurgical Industry

Bamboo biochar briquette serves as an eco-friendly reducing agent in metal smelting. It can replace traditional coke and coal, aiding in the removal of oxygen from metal ores and promoting metal extraction. Compared to fossil fuels, bamboo biochar briquette offers the advantage of lower carbon emissions.

Top 3 bamboo charcoal briquette making proposal for your choice

According to different customer’s requirements, we can provide you with three price solutions for bamboo charcoal briquette making machine.

NO.3 Rice husk biochar briquette production line

Rice husk biochar briquette machine can make the rice husk to charcoal briquette for further usage. It is a way to recycle the rice husk and make value from the product.

Market potential of rice husk charcoal briquettes production business

Everyone has heard that the raw materials for making biomass charcoal briquettes are generally woody and coconut shells. In recent years, the development of rice husk charcoal briquettes has been getting better and better. Many people don’t understand rice husk charcoal briquettes very well. In fact, the price of rice husk raw materials is low. So the price of rice husk biochar briquettes is lower than that of wood charcoal briquettes, which is very suitable for investors to start low-cost processing business.

Rice husk charcoal briquette making machine cases

- 1

Project background: Bamboo resources are abundant in this country. This customer wanted to put the raw materials to good use.

- 2

Solution: 500-1000 kg/h rice husk charcoal briquette plant and 1-10 t/h rice husk biochar briquette making line.

- 1

Japanese customer background: This customer has a substantial supply of rice husk with low moisture content.

- 2

Solution: Top 2 rice husk charcoal briquette making methods – carbonization furnace + charcoal wheel grinder + charcoal briquette maker(carbonization first & then forming method) / charcoal extruder + hoisting or batch type carbonization furnace (forming first & then carbonization method)

The above is the most 3 hot selling charcoal briquette plants from SX in the past ten months 2023, And except for them, there are many other high quality biochar briquette lines on sale. For example, coconut shell charcoal briquette making line, wood charcoal forming line, biomass charcoal briquette system, etc. If you are interested in them, please contact us. We will provide you with high quality charcoal forming machines at a favourable price!