Charcoal ball press machine is a roller-type briquette press that can compress charcoal powder into ball and pillow, etc shape briquettes. It is one of the key equipment in biochar briquettes production. Our company designs this machine with many years of experience in charcoal briquettes making. So the quality of roller press briquettes machine is guaranteed. And this machine can not only use mechanical force to make briquettes, but also adopt hydraulic system achieving biochar briquettes production. For this, more and more charcoal briquettes manufacturers prefer to use it to produce briquettes.

How does a charcoal ball press machine work in biochar briquettes making?

It is a simple process to manufacture biochar briquettes. Firstly you can feed raw materials into the hopper of the ball press machine. Then the screw propeller in the hopper rotates and pushes the raw material forward. During this process, two rollers make use of physical force to compress materials and the pressure gradually increases. For this, die holes of the ball press machine force out the compressed material in the form of briquettes or balls.

How to choose materials for briquettes making in charcoal ball press machine?

According to customer’s different requirements, we design a roller press briquetting machine which can adopt various materials and shapes of briquette.

Briquette making materials types

Charcoal briquettes preparation materials requirements

Here is an example:

In biochar briquette making process, when using lime and clay as binder, the moisture should be between 18-20%. but when you use pulp or sodium humate as binder, the moisture requirement change into 10-12%. So if the binder is asphalt, the moisture even low to 2-4%!

Why do you need to add binders before charcoal briquetting process?

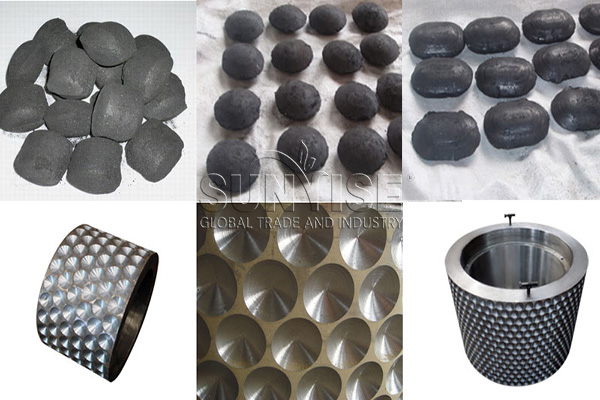

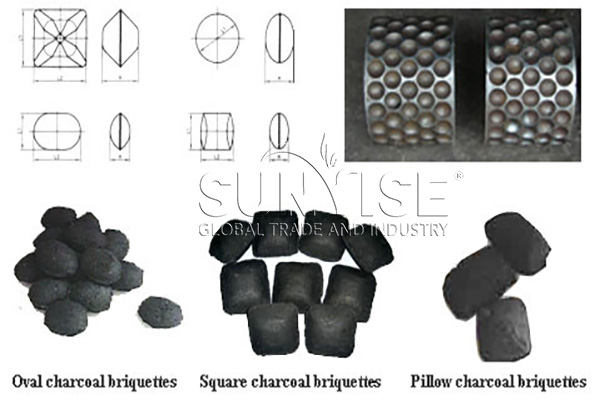

Final product of charcoal ball press machine

The shape of the biochar powder briquetting machine is determined by its mold. So we can provide customers with pillow, spherical, bread, and other molds. Moreover, we customize mold patterns and texts for customers. The following is the different shapes of final product image:

How much does roller press briquetting machine cost?

Finally, the price of charcoal ball press machine is an item most customers pay attention to. And it is a major factor in determining whether customers are willing to buy this charcoal briquettes making machine. The price of this machine on the market is about 3,500 dollars/set to 58,000 dollars/set in 2024, and varies with its capacity and configuration. If you want to know detail price of biochar ball pressing machine you need, you can contact us.

Roller press briquette machine plant for sale

You can use the charcoal ball pressing machine alone and combine with other equipment to form a charcoal briquettes production line. Feeder machine, crusher, mixer, belt conveyor and dryer, various combinations, you can choose as you need.