With the increasing demand for charcoal briquette and the need for biomass waste disposal. More and more companies choose to extend their business to the field of charcoal briquette production. And most of them plan to build a charcoal briquette production line. During this process, charcoal briquette machine price is an important factor in which method and equipment they choose to produce biocar briquette. As a professional char-molder manufacturer, YS designs charcoal briquette plants with different budgets for your choice. If you have any special requirements, we also can provide customization service for you. So if you are interested in it or want to know more details, please contact us quickly.

What is the charcoal briquette machine cost?

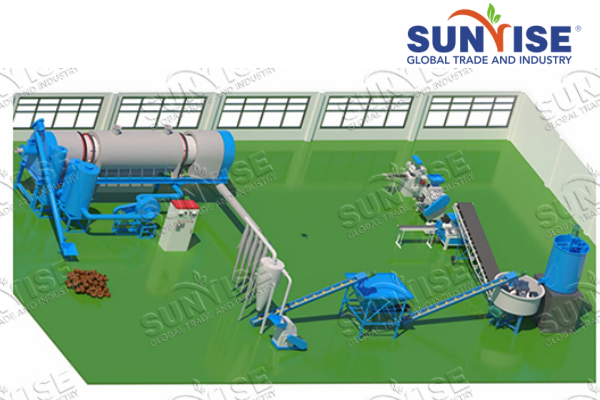

Do you want to setting up a biochar briquette factory? To begin with, you should determine which one charcoal briquette processing line to use. According to the use of different raw materials and techniques, charcoal briquette making line has different equipment configurations, and its cost is not the same.

Small factories select a manufacturing line that produces 300-500kg biochar briquette per hour, covers an area of around 200-500㎡, and costs between $11,000 and $62,000 USD. Thus, you can purchase our hoisting carbonization machine and hookah press machine, as they can work in the small area.

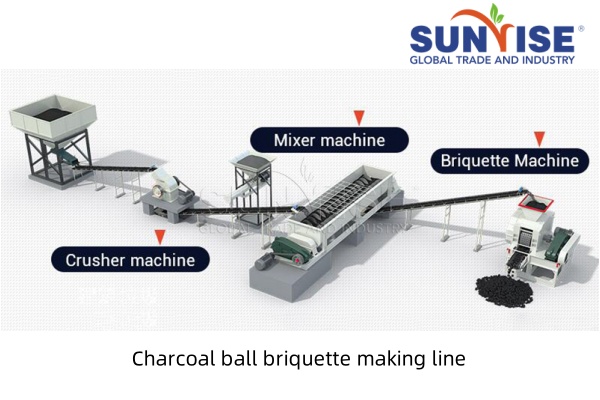

What is the price of charcoal ball press making line?

It is not fixed, and varies with capacity, Generally, a 1-10 t/h charcoal ball press making line is $29,000-$200,000; Starting a 10-15 t/h roller charcoal briquette plant setup needs $200,000-$300,000; The price of a 15-30 t/h granular fertlizer manufacturing system is $300,000-$500,000. If you need detail quotation of your charcoal ball press making line, you can contact us immediately.

How about the ROI of the charcoal briquette plant?

Although it is high of the investment of charcoal briquette production project, the same as the returns. Both of charcoal extruding line or hookah press briquette plant.

Top 3 factors affect the charcoal briquette machine price

Buy a commercial charcoal briquette machine is essential for transforming biochar powder into valuable charcoal briquette. However, the price of these machines can vary widely. Here, understanding the key factors affecting cost of charcoal briquette making equipment is crucial for making an informed purchase. Here are the top 3 factors to consider.

What other aspects you need to consider for commercial charcoal briquette machine cost?

When you buy a charcoal briquette plant, you also need to consider other aspects besides equipment price.

The quality of after-sale service can make a considerable difference in the long-term value of your charcoal briquette machine. Considerate after-sale service can greatly reduce the cost of biochar briquette production. Here, SUNRISE can offer you service of operation guidance, equipment installation, repair and replacement of non-human damage, etc.

Maintenance is an inevitable part of operating any charcoal briquette machinery. Regular servicing, replacement of worn-out parts and repairs contribute to ongoing expenses. Our biochar briquette making machine has a reputation for reliability and easy maintenance. So it can minimize the costs of charcoal briquette production over time.

The operational cost must be factored in, which includes labor, electricity, and raw material handling. Efficient charcoal briquette machines from SUNRISE are easy to operate can reduce labor costs, while those with energy-saving features can lower electricity expenses.

How to purchase charcoal briquette machine with lower investment?

There are many factors that affect the cost of building a charcoal charcoal plant. So besides the choice of production line, you can also reduce the cost of building your biochar briquette making line from these aspects.