In order to meet the strong market for charcoal, we designed three types of carbonization furnaces according to customer’s advice. Including hoisting carbonization machine, horizontal carbonization furnace and continuous carbonization machine. You can choose a suitable one for charcoal production.

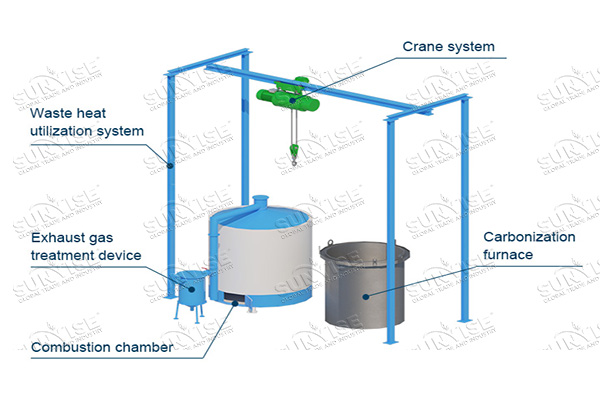

NO.1 Hoisting carbonization furnace

The airflow carbonization furnace contains an inner container. And you can put the raw materials into the inner container. Then the inner container is put into the furnace body. After completing the charging, the fuel is burned in the combustion zone below the inner container to heat. Furthermore, the fire heats the surface of the inner tank without direct contact with the raw materials. So we call it external heating or retorting. The temperature in the inner tank continues to rise, and eventually, carbonization begins after reaching a certain temperature.

What is the detailed information for designing hoisting carbonization machine?

NO.2 Horizontal carbonization furnace

The horizontal charcoal furnace is the carbonization equipment for processing various charcoal. This is another type of air-flow type charcoal making machine, which can not only carbonize wood chips, branches, bamboo, coconut shells, and logs, but also biomass briquettes, such as sawdust briquettes. And the main structure of the horizontal carbonization furnace includes an outer shell, an inner liner, a pipe, and smoke gas purification equipment, etc. Due to its large output and simple operation, this charcoal machine is very popular among charcoal processors.

2 different usage ways of horizontal carbonization machine

According to customer’s requirements, we especially design this carbonization furnace for 2 usage ways.

Option 1

- Crush the raw material to certain size with a charcoal grinder machine

- Dry the crushed material with a suitable dryer

- Compress the material to certain shape with a charcoal extruder machine

- Carbonize the briquettes to charcoal briquettes with a horizontal carbonization furnace

Option 2

- Carbonize the raw material with this batch type carbonization furnace

- Crush the carbonized material with a professional charcoal wheel grinder

- Mix the powdery material with binders through using a double shafts horizontal mixer

- Compress the mixed material to charcoal briquettes with a charcoal briquette extruder machine

NO.3 Continuous carbonization machine

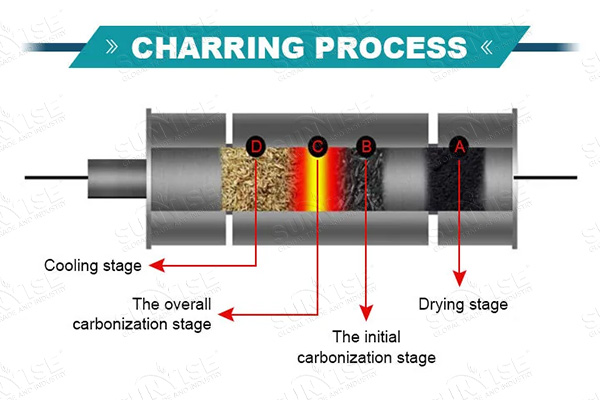

A continuous carbonization furnace is a type of industrial equipment used for the continuous carbonization of biomass materials. And it is designed to convert biomass, such as wood chips, sawdust, rice husks, coconut shells, and agricultural residues, into charcoal through a controlled pyrolysis process.

What is the new design of continuous carbonization machine?

Comparison Table of Carbonization Furnace

| Type | Processing Mode | Automation | Output | Efficiency | Investment Cost |

| Hoisting | Batch | Low | Low-Medium | Moderate | Low |

| Horizontal | Batch | Medium | Medium | Higher than hoisting | Medium |

| Continuous | Continuous | High | High | Very High | High |