Rice husk is the protective coat around rice seeds. It is a waste material that is obtained in tons during the rice harvesting season. And the most abundant components present in rice husk are cellulose, lignin, and silica. Due to the high percentage of lignin (natural binding material) and low water content, rice husk is a valuable raw material to make charcoal briquettes for household or industrial uses. For this, on 15th June 2024, a customer from Japan wanted to purchase a set of rice husk charcoal briquette machine. The following are the specific details of communication in this case:

Top 2 rice husk charcoal briquette making method

This Japanese customer wanted to know the method of making rice husk biochar briquette. In general, there are two ways of making charcoal briquette from rice husk. The one is directly carbonizing rice husk into charcoal through a carbonization furnace, and then compressing the rice husk charcoal into briquettes. The other is to compress rice husk into briquettes first by the rice husk briquette machine, then carbonize the rice husk briquettes into charcoal.

Carbonization first & then forming

This method is suitable for customers with sufficient budget. Because rice husks are very small and the only carbonizer suitable for this feed size is a continuous carbonization furnace – 5-20 mm. Usually, rice husk as a fine particle material does not need to be further crushed, you can feed it directly. After that, you can use charcoal wheel grinder to make charcoal powder. Finally, there are four charcoal briquette making machines for your choice to produce rice husk biochar briquettes.

Forming first & then carbonization

The moisture content in the rice husk is up to 15%. However, it is suggested that the raw material should have 8% to 10% moisture in it. So you need a dryer to reduce the moisture content. And to reduce the cost of rice husk briquetting, it can also be placed under the sunlight to decrease moisture content through evaporation. Since rice husk is small in size, so there no needs for crushing. After drying, you can directly feed it into charcoal extruder machine. Finally, through using hoisting carbonization machine or batch type carbonization furnace, you can get rice husk biochar briquette.

What is the price of rice husk charcoal briquette plant?

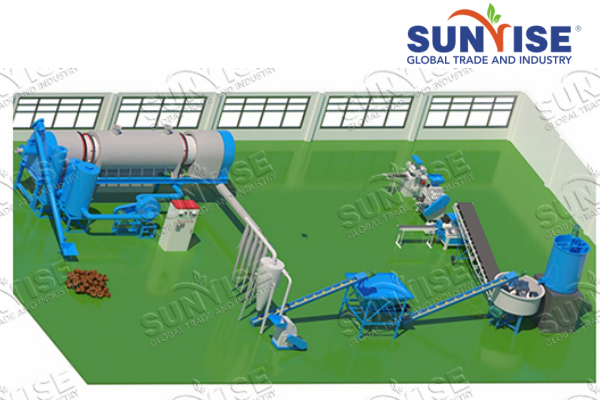

Then the customer from Japan also wanted to know the price of rice husk biochar briquette plant. And the cost of rice husk charcoal briquette production usually varies according to capacity, equipment configuration and many other factors. Here we will show you the prices of 500-1000 kg/h small scale rice husk charcoal briquette production line, 1-10 t/h rice husk biochar briquette making line and 10-30 t/h large scale rice husk charcoal briquette manufacturing system for your reference.

500-1000 kg/h

- 600-1050㎡

- (Reference)

1-10 t/h

- 1250-3000㎡

- (Reference)

10-30 t/h

- 3000-4000㎡

- (Reference)

Is there a lower investment rice husk charcoal briquette making plan?

Of course. The above is the price of the highest configuration business plan machines. In addition, we can offer you two basic designs. For example, for one basic carbonization furnace + charcoal wheel grinder + charcoal briquette maker, you only need to prepare $5,000-$23,000 (carbonization first & then forming method). As for another design, with charcoal extruder + hoisting or batch type carbonization furnace (forming first & then carbonization method). About $ 8,000-$23,000.

What is the use of rice husk charcoal briquette from Sunrise machine produced?

Finally, Japanese client prepare to get more profits from these rice husk biochar briquettes. So he asked us the use of rice husk charcoal briquette. In addition to being used as fuel, rice husk charcoal briquette is also widely used in industry and agriculture.

Rice husk charcoal briquette production line is an ideal choice for beginners production. But if you want to produce small scale rice husk biochar briquette, you can choose our small scale rice husk charcoal briquette production plan.