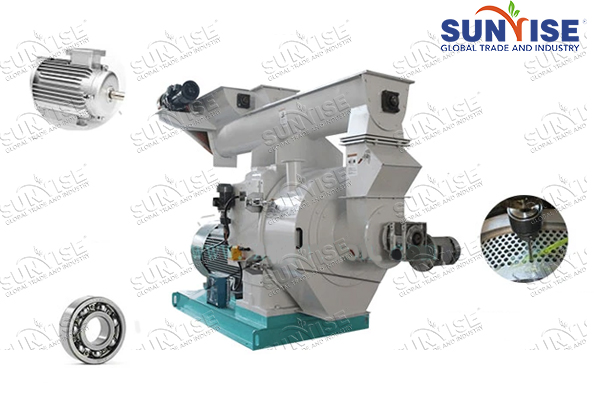

Speaking of pellet machine, almost people know it is used to make renewable fuel for daily use. But Sunrise found that the pellet machine also can be used for producing charcoal pellets, which is named as charcoal pellet machine. According to the different working principle, charcoal pellet making machine is divided into two kinds, including flat die type and ring die type. The former is designed with flat dies, four kinds of driving power is equipped, including electricity engine, diesel engine, gasoline engine and PTO; while the later is developed with ring die which is like a “ring”. Both of these two types can process high quality charcoal pellet.

Top 2 charcoal pellet making machines for your choice

As a professional charcoal pellet equipment supplier, we can provide you with various charcoal granulation machines for material processing. Among them, there are 2 types of charcoal pellet machine that are popular with granular charcoal manufacturers. They have different features and are suitable for different occasions, you can choose the right one according to your needs.

Flat die granulation machine for small scale biochar pellet making

Are you finding a charcoal pellet making machine for your small scale biochar pellet production? Our flat die pellet mill is an ideal choice for you. Why? Because it has features as follows:

Ring die pellet machine for commercial biochar pellet production

For those who produce charcoal pellet for commercial purpose, we recommend you choose our ring die pellet mill. Because it is beneficial for the following aspects:

Ensure the continuous charcoal pellet supply to your customer

Using our ring die pellet making machine, you can finish the whole granulation process in 10-20 seconds. Therefore, its output can reach 1-2.5 t/h. That is, it can process 7,500 tons of charcoal granules from material a year. This definitely can ensure the continuous biochar pellets supply to your customer.

Improve the quality of your final charcoal particles

To make more profits from charcoal pellet making, you also need to pay attention to further improving the quality of your pellets. This charcoal pellet making machine employs the mechanical extrusion force to prepare biochar pellets. So the final charcoal pellets products have characteristics of beautiful appearance, uniform particle size, high hardness, low pulverization rate, etc.

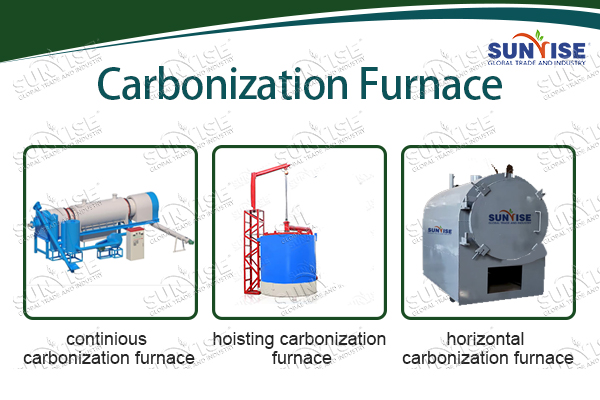

How to establish a charcoal pellets making line?

To start commercial charcoal pellets making and biochar granulation plant setup more smoothly, it is necessary to establish a charcoal granulation line. So besides granulation equipment, you may need the following biochar pellets processing machines.

What is the cost of your charcoal pellets production lines?

The price usually plays an important role in charcoal pellets production line selection. Then in terms of cost, our biochar granulation systems can be divided into two parts:

What is the key different from charcoal pellet making machine and char-molder?