On 15th November 2024, a customer was looking for a supplier of a turnkey production line for the manufacture of charcoal briquette made from different materials. “I was the CEO of the company PROVALOA which provides technical solutions to Tanzania companies in the field of food and energy processing. So please send us the quote of a complete line to produce 1000 kg/h.” For this, we send him a YS-140 charcoal extruding line. The following are the specific details of communication in this case:

What is the design of 1000 kg/h charcoal briquette making in Tanzania?

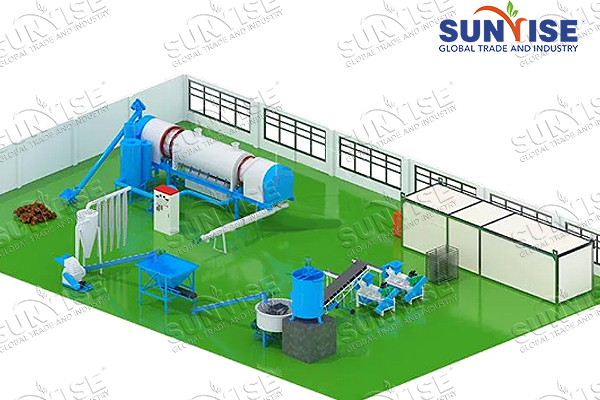

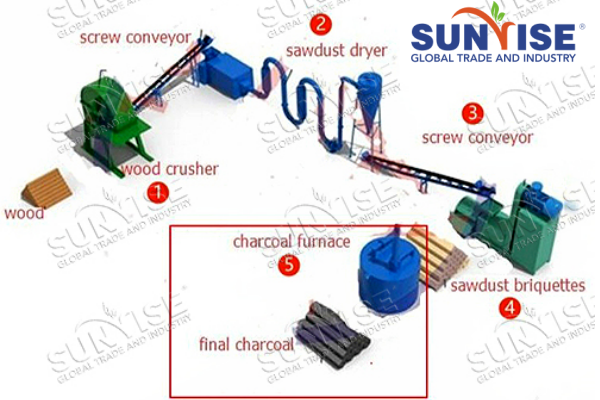

Because the Tanzanian customer required a 1000 kg/h of charcoal briquette production, the charcoal extruding line is the best choice. Here, as the general charcoal briquette making plan, it main contains 8 parts according to customer’s requirements. Hammer mill > sun drying > semi-conitunous carbonization furnace > charcoal wheel grinder > double shafts horizontal mixer> charcoal extruder machine > sun drying > charcoal packaging machine. What different are the following 3 aspects:

What is the price of 1000 kg/h charcoal briquette production line?

Then, on 15th November, the charcoal briquette manufacturer from Tanzania came to our YUSHUNXIN char-molder factory in China. He wanted to learn our charcoal briquette machines deeper and get precise costs of the charcoal briquette making system.

During this communication, he told us that he set up a charcoal factory in Togo in 2018, and wanted to rebuild a factory and replace his equipment. In general, this charcoal briquette production line costs $70,000-$160,000. Then because we are in Procurement Festival, there is a 8% discount. The final quote of the 1000 kg/h biochar briquette production line is $64,400-$147,200.

How much deposit do I need to pay for the charcoal briquette machine?

Generally speaking, the larger the deposit you pay, the greater the discount you will receive. Whether it is in charcoal briquette equipment deals or not. Here, it is advisable to pay you pay a deposit of more than 30% when ordering biochar briquette machine. Especially the large scale charcoal forming equipment. The remaining payment for the charcoal briquette machines can be settled upon delivery. Finally, the customer from Tanzania paid 50% deposit to us by credit certificate.