We know that the key equipment for producing charcoal is the charcoal briquetting equipment. After extruding and forming the raw materials through using this machine, we can see the desired end products very intuitively. However, briquetting is only one part of the entire charcoal briquette production line, and briquettes machine is just one of all charcoal making machines. If you want to make charcoal briquettes, you also need other auxiliary equipment. So, we mainly talk about auxiliary charcoal making machines as follows:

Carbonization furnace

If you need to make charcoal, in addition to using traditional earth kilns to make biochar, you can also choose new carbonization furnace equipment. The main raw materials for making charcoal are various types of trees.Such as the quality of charcoal made from harder wood is relatively good. And wood blocks from wood furniture factories, scraps from flooring factories, and larger fruit shells (coconut shells) can be carbonized into charcoal.

Why do you choose new carbonization furnace equipment?

With the increasing global awareness of environmental protection, these traditional earth kilns are becoming increasingly rare. Why? This is because when the earth kiln is firing charcoal, the smoke is particularly large, polluting the environment. Another issue is that the carbonization time is too long, taking about 10-15 days. And the time for charcoal production is generally about 5-7 days. Based on the above disadvantages, the new mechanism carbonization furnace has replaced the earth kiln and is receiving more support.

There are also three types of carbonization furnaces for your choice.

Vertical hoisting carbonization furnace

This type of furnace can carbonize both raw wood materials and machine-made charcoal briquettes. And its biggest feature is the production of smokeless carbonization throughout the entire process. And this vertical carbonization furnace can have multiple inner tanks. This can lead to multiple carbonizations in one furnace. After completing a batch of carbonization, you can remove the inner liner for cooling and the next batch of carbonization can continue. This cycle carbonization saves time.

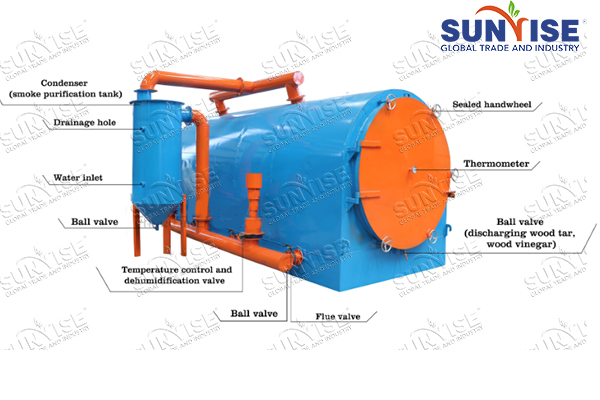

Horizontal carbonization machine

This type of carbonization furnace has a variety of specifications. And customers can choose models with different production capacities according to their needs. If your factory is not enough, it is recommended to use a small carbonization furnace. After all, the footprint is relatively small, the volume is also small, and it is simple and convenient to use. What’s more, the advantage of a horizontal carbonization furnace is that it can recycle and reuse the combustible gas produced.

Continuous carbonization equipment

It is suitable for making large scale charcoal with the capacity of 100-3800 kg/h. When you want to achieve the continuous production of biochar, this continuous carbonization furnace is an ideal choice. And it is also configure dust removal system, which can protect your production environment. But when you choose this machine, you need to process your materials in advanced.

Crusher and mixer

If the end product you want to make is not charcoal, but charcoal briquettes with a specific shape, you will need more auxiliary charcoal making machines. Such as crusher and mixer.

Wood crusher

A wood crusher is a highly practical equipment. It is suitable for a wide range of raw materials, including wood, branches, and various wood processing waste. And the size of the finished product ranges from 3mm to 20mm, which can meet different usage needs. This crusher machine has low cost but large output. So it can be used as an auxiliary equipment for charcoal briquette production, as well as for other wood processing plants. Besides this, we can also provide you with other grinders, such as hammer mill and Raymond mill, etc.

Charcoal mixer

There are two types of mixing machines for your choice. Charcoal mixer and double shafts horizontal mixer. The first one can not only blend materials but also re-grinding charcoal. So one machine with multiple uses is very economical. And the second one is suitable for adding some binders when you blend materials. You can select them according to your needs.