The coconut shell is composed of coconut fiber (up to 30%) and pith (up to 70%). Its ash content is about 0.6% and lignin is about 36.5%, which helps to turn it into charcoal fairly easily. And coconut shell charcoal is a natural and environmentally friendly biofuel. It is the best fuel substitute against firewood, kerosene, and other fossil fuels. In the Middle East, such as Saudi Arabia, Lebanon, and Syria, coconut charcoal briquettes are used as hookahs coals (Shisha charcoal). While in Europe, it is used for BBQ (barbecue). So master the technique on how to make best coconut shell charcoal briquettes, it will bring you great wealth.

Where to get cheap and abundant coconut shells?

To build a profitable coconut charcoal briquette production line, what you should do first is to collect large quantities of coconut shells.

According to the Statistics offered by the Food and Agriculture Organization of the United Nations (FAO), Indonesia is the world’s largest coconut producer, with a total production of 20 million tons in 2020. Indonesia has 3.4 million hectares of coconut plantation which is supported by tropical climate. And Sumatra, Java, and Sulawesi are the main coconut harvesting areas. The coconut shell price is so cheap that you can obtain abundant coconut shells in these places.

What is the process of making quality coconut biochar briquette?

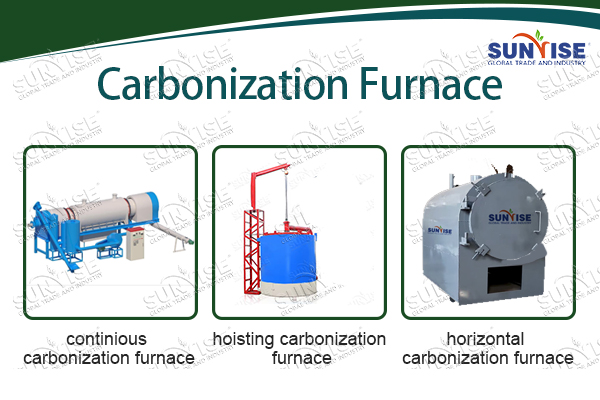

The coconut shell charcoal briquette making process is: carbonizing – crushing – mixing – drying – briquetting – packing.