There are many coconut shell charcoal products on the market, but the quality varies greatly. Why? This is because the charcoal processors have not mastered the method of processing high-quality coconut charcoal briquettes at the time of production. In particular, if the ash content of coconut shell charcoal briquettes is large, it will directly affect its price and sales. So, what can we do to reduce the ash content of coconut shell charcoal briquettes?

What is ash content of coconut charcoal briquettes?

The most common coconut shell charcoal briquette on the market is hookah biochar briquette. Due to its high calorific value and long burning time, coconut shell charcoal briquette is very suitable for processing various types of hookah biochar pellets.

Definition of ash content

The ash content of shisha charcoal briquette represents the quality of shisha biochar briquette. Ash content refers to the percentage of the original hookah charcoal briquette in the residue obtained after the hookah biochar briquette is fired at high temperatures.

What is the standard ash content of hookah biochar briquette?

Too much ash will reduce the burning time of hookah charcoal briquette. Therefore, the smaller the ash content, the better the quality of the hookah biochar briquette. Good quality shisha charcoal briquette requires that its ash content is not higher than 6% (weight basis).

2 Methods for making high quality coconut charcoal briquette

Ash content and the production of high quality coconut shell charcoal briquettes are inseparable. What methods are there to produce high quality coconut shell biochar briquette?

Choose suitable materials

There are many raw materials for making charcoal briquette, such as wood, rice husk, coconut shell, straw, and so on. However, the ash content of rice husk charcoal, straw charcoal, etc. is usually large. Therefore, it is best to use coconut shell charcoal, hardwood charcoal, etc. to process charcoal briquettes.

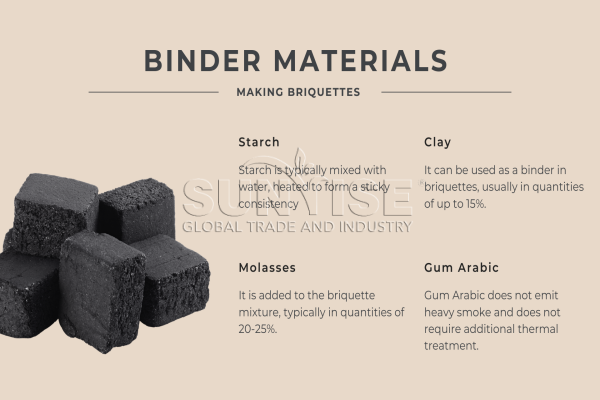

Use pure binders

We have to use adhesives wisely when processing charcoal briquettes. Before processing briquette charcoal with charcoal briquettes press machine, we usually pre-treat the charcoal powder by adding the appropriate amount of binder and water to the charcoal powder. What we need to pay attention to is that there are many types of binders. And different binders have different effects on the ash content of coconut charcoal briquettes. Therefore, we should choose the adhesive with fewer impurities and pure texture as much as possible.

Where to buy the right machine for making quality biochar briquette?

Buying good charcoal briquette machines is the basis of your high quality biochar briquette production. But where to buy these machines? Here, YS char-molder factory is an ideal choice for you. Why? There are 3 reasons as follows: