When you want to setup a sawdust charcoal briquette production plant, there are four things you need to do: finding materials supplier, finding a place, buying suitable machines and gaining production license. Through the above process, you can build a high quality sawdust biochar briquette plant.

Finding stable charcoal briquette making material supplier

Only you have stable material supplier, you can continuously produce enough briquette product to deliver to your customer. You can partner with local farmers and sawmills to buy their waste. Such as wood waste, wood shaving and sawdust, etc. These are rich in lignocellulose and lignin, etc. So they are excellent materials to make charcoal briquette. Doing this also can contribute to reducing environmental pollution.

Finding a suitable place for your sawdust charcoal molding plant

The briquette preparation factory is better to build in a place which is close to raw material sources, away from residential areas and has good transportation conditions.

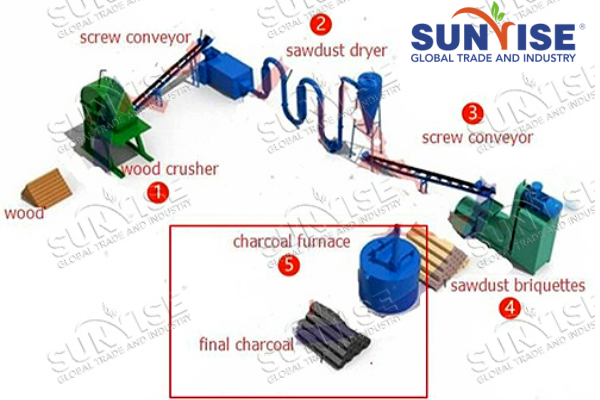

Buying suitable charcoal processing equipment

Equipment plays an important role in biochar briquette manufacturing. When you purchase machines for your sawdust charcoal briquette making, you need to consider your actual conditions. Such as capacity, type, material, budget, factory area, etc. YS has all equipment of a complete sawdust charcoal briquette production line for your choice. And we can recommend you high quality biochar briquette machine according to your requirements and provide them to you at a favourable price.

Gaining production license

It is the same as charcoal briquette machine manufacturing. Only get all licenses, you can set up your sawdust charcoal molding plant and start sawdust biochar briquette preparation. Therefore, you need to send the briquette product you produce for testing. If it is qualified, go to the government department for registration, then you can obtain the production license.