Briquetting process converts low bulk density biomass materials into high density fuel briquettes. In the briquetting plant, in order to make high quality biochar briquette, you can compress ground charcoal burned from sawdust and other wood by-products into briquettes along with a binder and other additives that helps the briquette to burn. The selection of binder and additives is related to the quality and cost of the charcoal briquettes.

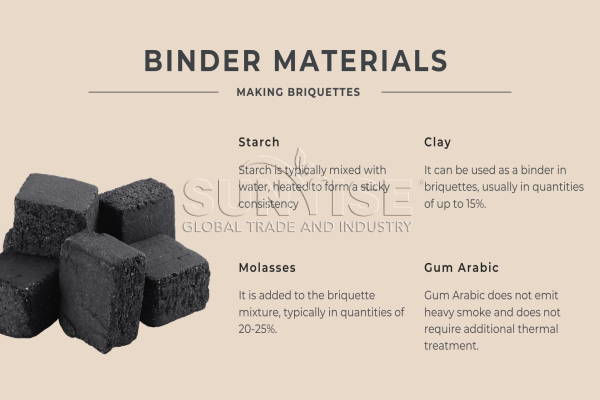

5 Binders to make high quality charcoal briquettes

Charcoal is totally lack of plasticity, thus it needs addition of a binding material to hold the briquette together for transportation, briquette forming and storage. Every particle of biochar is coated with binder, which enhances charcoal adhesion and produces identical briquettes. After the wet pressed briquettes are dried, the completing the binding operation. Starch, clay, molasses and gum Arabic are common types of briquette binders.

Besides, cow dung and paper pulp also can be the binding material for briquettes. Cow dung is available mainly in farms. Waste papers are torn to small pieces and soaked in water to form a gelatinized paste.

Do you have other additives to add for quality biochar briquette making?

Besides the binding materials, you can also add some additives to prolong the burning time of biochar briquettes.

Accelerant

Briquettes are not able to absorb sufficient oxygen for faster combustion due to compaction. Sodium nitrate gives out oxygen when heated, so it is used as ignition aid for briquettes, helping the briquettes to light faster. Needing about 3-4% of sodium nitrate for briquetting. Sawdust burns quickly and is also used as ignition aid. The amount of sawdust needed is about 10-20%.

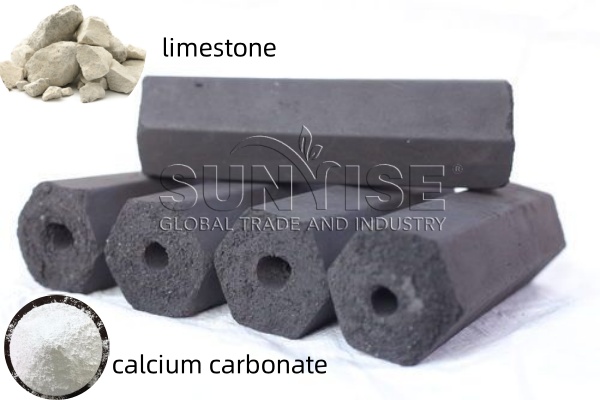

Ash-whitening Agent

White ash color looks nicer and acts as a signal that the briquettes are ready to cook on. A 2-3% lime, limestone or calcium carbonate is sufficient to make the ashes turn white. They are not heat fuels but can lower the burning rate to make the briquettes burn longer.

Press Release Agent

Using borax or sodium borate in small amounts to help briquettes release from the manufacturing presses. But it is not necessary to use this press release agent if you are using simple press or manual press. It is only necessary when using a high speed and high pressure briquette making machine.

In order to mix these binders and additives with charcoal powder evenly, charcoal mixer is necessary. In YS, we can provide you with types of biochar blending machines for your choice.