Nowadays, more and more people are prone to invest in charcoal briquette making. Why? One the one hand, providing long-lasting heat compared to traditional non-renewable fossil fuels. On the other hand, charcoal briquettes burn without smoke or odor. So making charcoal briquette is an ideal choice. Provided you are a beginner or want to start with small scale biochar briquette manufacturing, you can buy our 500 kg/h charcoal briquette production line.

What do you need to do for starting 500 kg/h charcoal briquette making?

Before starting 500 kg/h charcoal briquette manufacturing, you need to know what you should do for it. Generally, you need to pay attention to 3 items: materials, plant location and equipment selection.

In general, you can make 500 kg/h biochar briquette with 3 kinds of materials. Biomass material: bamboo, wood, coconut shell, rice husk, etc; Agricultural waste: straw, sawdust, etc; Other waste: branch, various fruit shells, wood shavings, etc. It is advisable to use the first two as the main material for charcoal briquette making and the last as auxiliary materials.

Then suitable equipment purchasing is essential for smoothly 500 kg/h charcoal briquette production. For this, you need to know what machine is needed in 500 kg/h biochar briquette making? How much does the 500 kg/h charcoal briquette making system cost? Can your small charcoal briquette factory accommodate it? But don’t worry, we will help you. Even we can offer you customized design according to your requirements.

For 500 kg/h charcoal briquette making plant setup, there are three tips for you. Avoiding building in areas where local policy prohibits. Located in a place with convenient transportation. And setting it up close to raw material sources.

What is the design of a 500 kg/h charcoal briquette plant?

In general, as a professional char-molder equipment factory, YS will design business plan according to your actual conditions. In this process, capacity is an item we must consider. Then what equipment is used in a 500 kg/h charcoal briquette production line? For this, we recommend you purchase the following equipment:

Small scale carbonization furnace

When you plan to turn materials into charcoal briquette, you need to make charcoal firstly. For small scale biochar production, many charcoal briquette suppliers will choose our hoisting carbonization machine or horizontal carbonization furnace. The former is a more economical choice for you while the latter can help you finish charcoal making more quickly.

YS-11 charcoal wheel grinder

Because charcoal wheel grinder employs stainless steel crushing wheels. It have a longer service life and can grind charcoal into fine powder quickly. In addition, it makes no noise and has low consumption during operation. Therefore, you can use it for a long time.

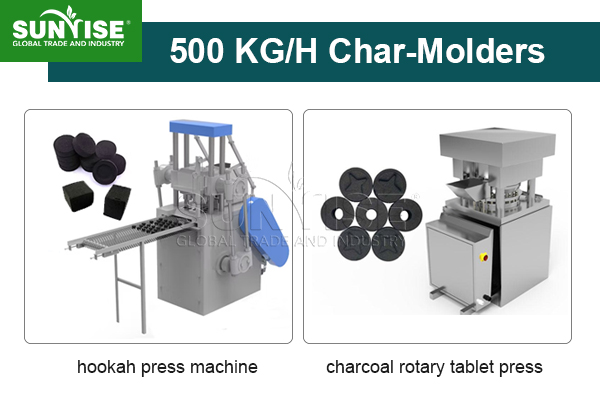

Charcoal forming equipment

For 500 kg/h charcoal briquette production, charcoal rotary tablet press and hookah press machine are hot selling products. For one thing, their briquette rates can reach 93%. So you can turn charcoal powder into briquettes more effectively. For another, they have smaller space occupation and favorable price, which make you spend less on 500 kg/h charcoal briquette manufacturing system setup.

Automatic packaging machine

Finally, you need to pack charcoal briquettes. But manual bagging will take a long time. So we design automatic bagging machine for you.