Charcoal briquette dryer machine is one of the necessary equipment for the charcoal briquette production line. It mainly adopts the principle of hot air circulation. Therefore, it can run stably. Moreover, it can dry materials at any time regardless of the weather. So, charcoal briquette dryers are popular equipment in many charcoal briquette making factories.

Charcoal briquette dryer machine is one of the necessary equipment for the charcoal briquette production line. It mainly adopts the principle of hot air circulation. Therefore, it can run stably. Moreover, it can dry materials at any time regardless of the weather. So, charcoal briquette dryers are popular equipment in many charcoal briquette making factories.

What is charcoal briquette dryer?

A charcoal briquette dryer is a machine used to reduce the moisture content of raw charcoal briquettes. This is typically done before the briquettes are packaged and sold. As moisture can make them difficult to light and can also promote the growth of mold and other microorganisms. And charcoal briquette dryers are usually composed of a drying chamber, a heat source, and a ventilation system. The heat source is typically a gas or electric heating element, and the ventilation system is used to circulate air through the chamber in order to promote evaporation of the moisture from the briquettes. Then some dryers can also have the feature of controlling temperature and humidity also.

A charcoal briquette dryer is a machine used to reduce the moisture content of raw charcoal briquettes. This is typically done before the briquettes are packaged and sold. As moisture can make them difficult to light and can also promote the growth of mold and other microorganisms. And charcoal briquette dryers are usually composed of a drying chamber, a heat source, and a ventilation system. The heat source is typically a gas or electric heating element, and the ventilation system is used to circulate air through the chamber in order to promote evaporation of the moisture from the briquettes. Then some dryers can also have the feature of controlling temperature and humidity also.

What are the raw materials for charcoal briquette dryer machine?

Charcoal briquette drying machines are generally used to dry formed charcoal. Such as shisha charcoal, biochar sticks, barbecue charcoal, etc. After drying with charcoal, the charcoal still maintains a good shape and will not destroy the exquisite shape of charcoal. And small-scale machines can also be used for drying fruits, medicines, plants, meat, and other products, with various functions. Besides these, after briquetting, it can also remove excessive moisture from charcoal briquette.

Charcoal briquette drying machines are generally used to dry formed charcoal. Such as shisha charcoal, biochar sticks, barbecue charcoal, etc. After drying with charcoal, the charcoal still maintains a good shape and will not destroy the exquisite shape of charcoal. And small-scale machines can also be used for drying fruits, medicines, plants, meat, and other products, with various functions. Besides these, after briquetting, it can also remove excessive moisture from charcoal briquette.

What types of biochar drying machines for your choice?

There are two types of charcoal briquette dryer machine for your choice. Including drying room and mesh belt dryer. You can choose a suitable one according to your needs.

There are two types of charcoal briquette dryer machine for your choice. Including drying room and mesh belt dryer. You can choose a suitable one according to your needs.

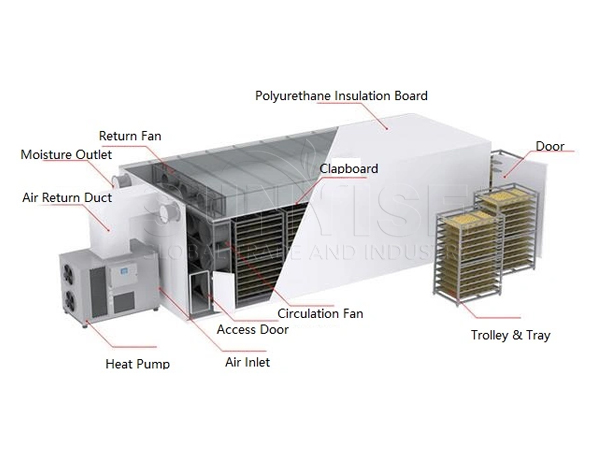

Drying room

The drying room adopts the working principle of a hot air circulation system and a dehumidification system. The temperature in the drying room is detected by an intelligent temperature control induction device. Although different materials have different drying temperatures. However, customers can set the indoor temperature and drying time through the power distribution cabinet of the coal briquette dryer to achieve the best drying state. Therefore, the oven dryer is a very smart and trouble-free device.

The drying room adopts the working principle of a hot air circulation system and a dehumidification system. The temperature in the drying room is detected by an intelligent temperature control induction device. Although different materials have different drying temperatures. However, customers can set the indoor temperature and drying time through the power distribution cabinet of the coal briquette dryer to achieve the best drying state. Therefore, the oven dryer is a very smart and trouble-free device.

What is the structure of charcoal briquette drying room?

What is the structure of charcoal briquette drying room?

Its structure mainly includes a heating source, induced draft fan, dehumidifier, hot air duct, control cabinet, trolley, tray, etc. It looks like a room. And the customer puts the finished product on the cart and pushes it into the drying room. Moreover, its size can be customized. Generally speaking, its size is related to the number of carts. Each cart has 10 layers.

Its structure mainly includes a heating source, induced draft fan, dehumidifier, hot air duct, control cabinet, trolley, tray, etc. It looks like a room. And the customer puts the finished product on the cart and pushes it into the drying room. Moreover, its size can be customized. Generally speaking, its size is related to the number of carts. Each cart has 10 layers.

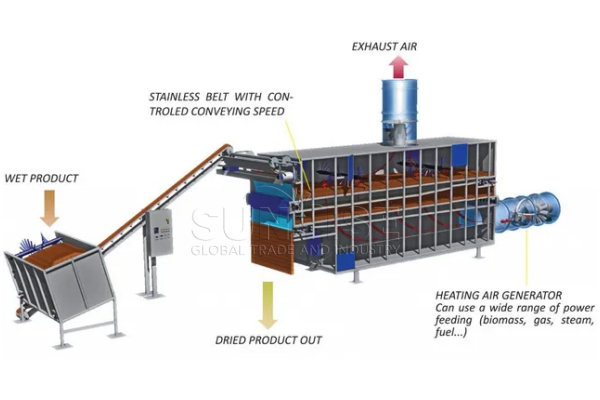

Mesh belt dryer

The operator needs to put the raw materials (such as briquette, charcoal, etc.) into the feeding port. The moving mesh belt then drives the charcoal briquette to spread out and enter the drying chamber for drying. The biochar briquette moves through the mesh belt dryer, and the hot air uniformly heats and dries the raw material. Moreover, customers can adjust the moisture content of the final raw material by adjusting the moving speed of the mesh belt dryer.

The operator needs to put the raw materials (such as briquette, charcoal, etc.) into the feeding port. The moving mesh belt then drives the charcoal briquette to spread out and enter the drying chamber for drying. The biochar briquette moves through the mesh belt dryer, and the hot air uniformly heats and dries the raw material. Moreover, customers can adjust the moisture content of the final raw material by adjusting the moving speed of the mesh belt dryer.

2 characteristics of mesh belt dryer for removing excessive moisture

2 characteristics of mesh belt dryer for removing excessive moisture

What is the heating method of charcoal briquette dryer machine?

How much does charcoal briquette dryer cost?

Finally, the price is an aspect most charcoal briquette manufacturers pay attention to when buying charcoal briquette dryer machine. However, it is not fixed and will vary with the output. The smaller the capacity, the higher the price; the larger the capacity, the lower the price. Then YS, as a reliable charcoal briquette equipment manufacturer, can provide you with quality drying equipment at a favourable price. It is about $8,000-$35,000. Provided you want to get a quote in detail, please contact us on the following contact form immediately.

Finally, the price is an aspect most charcoal briquette manufacturers pay attention to when buying charcoal briquette dryer machine. However, it is not fixed and will vary with the output. The smaller the capacity, the higher the price; the larger the capacity, the lower the price. Then YS, as a reliable charcoal briquette equipment manufacturer, can provide you with quality drying equipment at a favourable price. It is about $8,000-$35,000. Provided you want to get a quote in detail, please contact us on the following contact form immediately.