Compared with old style charcoal, biochar briquette have better fluidity. That is, charcoal briquette is more convenient to transport, store and use. Because after briquetting, your charcoal briquette has a lower possibility of sticking and layering. Therefore, more and more biochar briquette manufacturers invest in charcoal briquette production line. Thus, how to make biochar briquette? What equipment is needed in the char-molder plant? What is the price of a charcoal briquette plant setup? YS can provide you with all answers.

What equipment is needed in charcoal briquette plant?

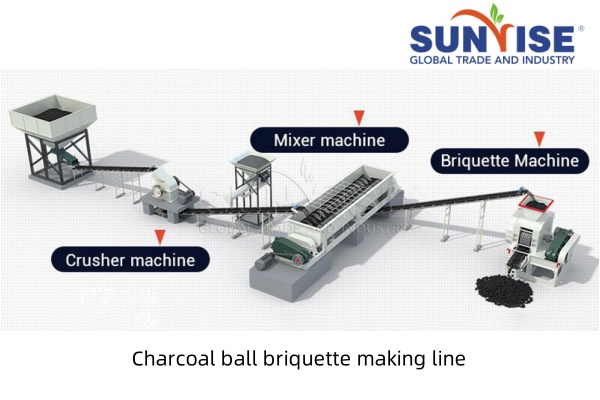

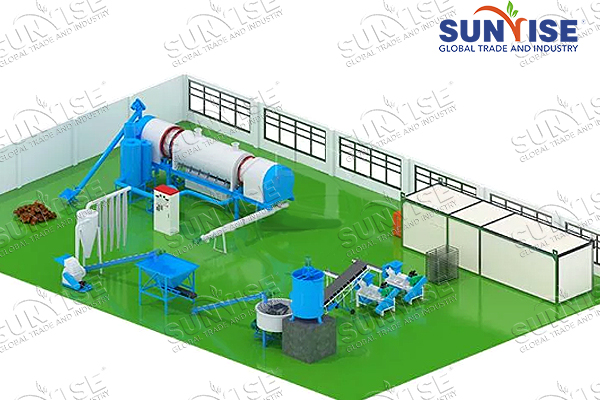

In order to make high quality biochar briquettes, it is necessary to understand the steps of a complete charcoal briquette production line. And what equipment is suitable for each process? A complete biochar briquette making system contains 6 steps as follows:

How many types of charcoal briquette making machines can you choose in YS?

Charcoal briquette production line, as name suggests, biochar briquette machine plays an important role in this system. But there are various char-molders in the market, which one is more suitable for you? There are some tips for your reference.

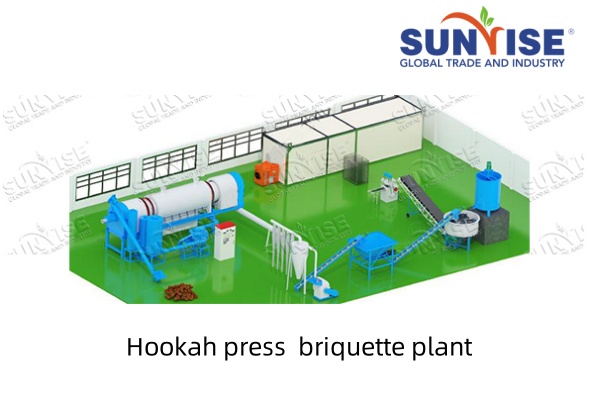

Small scale hookah press machine for low cost charcoal briquette making

If you want to start a small scale biochar briquette production, we recommend you choose hookah press machine. This machine includes two types, rotary type and impact type. And it is the most cost-effective small scale charcoal briquette machine in YS. For one thing, it has a capacity of 300-500 kg/h, which can fully meet your requirements of produce biochar briquette in a small scale. For another, it has a favourable price, only about $ 4,280- $ 18,000. And its briquette rate can reach over 99%. It means you can greatly reduce material consumption in the briquette process. Therefore, it can help you produce charcoal briquette at a low cost, whether it is shisha charcoal briquette making or bbq biochar briquette manufacturing.

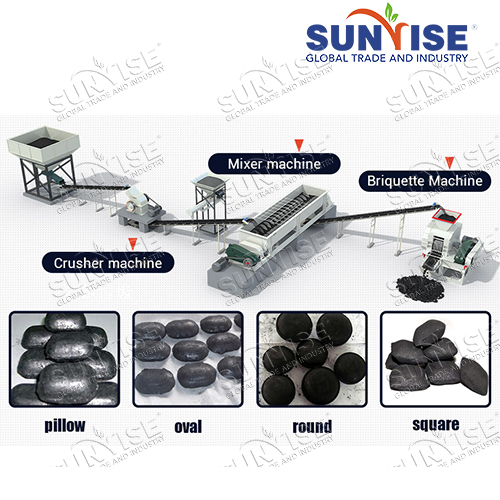

Large scale charcoal ball press machine for biochar molding

But when you want to buy a equipment for large scale biochar briquette making, the roller briquette press machine is your best choice. Because its largest production capacity is 30 t/h, which is much higher than any other char-molders. And in order to prevent the erosion of a large amount of charcoal briquette production, we especially use Q245 R steel and 310S stainless steel as equipment materials. Therefore, it can finish large scale biochar briquette production easily.

Charcoal extruder machine for rod shape briquettes making

The above two char-molders both produce round and square shape biochar briquettes. But is there a charcoal molding machine for rod shape briquette making? For this, YS can offer you biochar extruder machine. It mainly relies on the screw extrusion force of two metal heating rings to make charcoal powder into rod shape briquettes through screw-propeller. It can not only adopt wet material, but also involve dry materials. So you can use two charcoal briquette methods for biochar briquette making. Then this machine also can greatly reduce your budget for charcoal briquette manufacturing.

What is the price of charcoal briquette production line?

In the process of choosing production line for your biochar briquettes plant, price is an item you are interested in. You can know the detailed design and price of charcoal briquette production line from the following.