Charcoal extruder machine is a kind of briquette machine through using the screw structure to make rod shape briquette. And the most common use of this machine is for charcoal briquetting. So there are two methods. The one is molding first and then carbonization. The other one is that directly get rod shape briquettes (charcoal as materials). In addition, if you want to start continuous charcoal briquettes production, we can also meet your requirements.

What materials are suitable for charcoal extruder processing?

When you want to make briquettes from biochar extruder machine, you need to concern about the choice of materials. Such as type, size and moisture, etc. The following are the details:

Types of materials

Besides charcoal, this extruding machine can also produce briquettes from coke, sludge, olive pomace, sawdust and wood waste, etc. Different raw materials correspond to different briquettes production processes. So the selection of material is very important.

Requirements of materials

If you want to make high quality briquettes, materials need to get a certain requirements. For this, the size of materials is usually less than 3-5 mm. And 10-14 % is best moisture for briquette making on charcoal briquette extruder. Of course, you can make the briquette with other moisture, but there are disadvantages. With low moisture, the friction will be bigger which makes the briquette output slower. Then if the briquette with high moisture, it will be softer and takes more time to dry.

What is the other requirements of feeding materials in charcoal extruder?

Feeding materials into a charcoal extruder requires careful preparation to ensure efficient production and high-quality briquettes. Here are some key requirements and considerations:

By ensuring that these requirements are met, the charcoal extruder can operate efficiently, producing high-quality briquettes suitable for use as fuel.

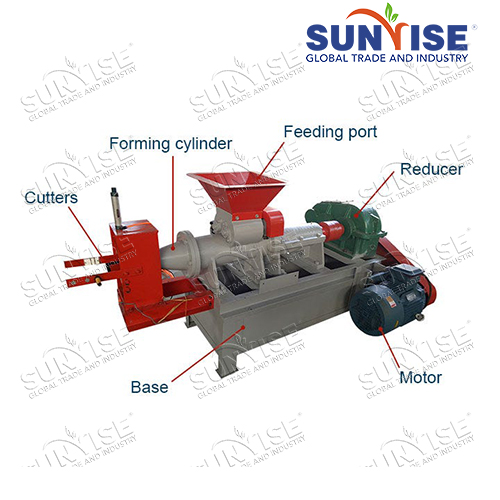

What is the working principle of charcoal extruder machine?

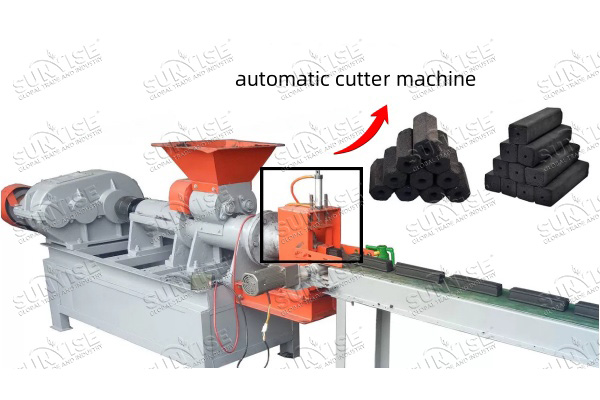

Simultaneously, the rotating screw applies pressure, forcing the softened materials through a die with a specific briquette shape and size. As the materials pass through the die, they solidify, forming tightly compacted charcoal briquettes. Finally, the charcoal briquettes are then cut to the desired length using a cutting mechanism. And the finished products are ready for packaging or immediate use.

Top 2 briquettes production methods in charcoal extruder for your choice

There are two briquettes production methods for your choice. The one is molding first and then carbonization. The other one is that directly get rod shape briquettes, which use charcoal as materials. The detailed information is as follows:

Which type of biochar extruder machine is suitable for your briquettes making?

It is common that different customers have different needs and requirements in production. As a professional and considerate supplier, we design various types of charcoal extruders for you. Whether you have a small, medium or large scale production line, whether you want to produce charcoal briquettes or other briquettes, they can meet your needs. Among them, YS-140 is the one with the smallest output, about 1-2 tons/h. It is an idea choice for you, if you want to start a small scale briquettes making. The largest output one is YS-210, about 3-4 tons/h, it is suitable for the medium scale charcoal briquettes production line. If you need larger scale production, you can use YS-400 biochar extruder machine to make briquettes. Its capacity can get 6-10 t/h.

| Model | YS-140 | YS-180 | YS-210 | YS-300 | YS-400 |

|---|---|---|---|---|---|

| Capacity | 1-2 t/h | 2-3 t/h | 3-4 t/h | 3-5 t/h | 6-10 t/h |

| Molding Specification | 20-40 | 20-60 | 20-80 | 20-80 | 20-80 |

| Speed of Mainshaft | 46-60 r/min | 39-60 r/min | 35-60 r/min | 35-60 r/min | 35-60 r/min |

| Number of Spiral Blades | 4 | 4 | 4 | 4 | 4 |

| Electrical Machinery | Y160m-4 11kw

Y160l-4 15kw |

Y180m-4 18.5kw

Y180l-4 22kw |

Y200l-4 30kw

Y225g-4 37kw |

Y225g-4 37kw

Y225m-4 45kw |

Y315m-4 160kw |

| Reduction Dive | ZQ350 | ZQ400 | ZQ500 | ZQ650-750 | ZQ850 |

What other machines you need to make high quality biochar briquettes?

Besides charcoal extruder machine, there are some other machines can help you produce high quality rod shape biochar briquettes. (The following equipment is only configured around the charcoal extruder.)

automatic cutter machine with charcoal extruder equipment

In order to meet customer’s requirements about the length of charcoal briquettes, we usually equip charcoal extruder with an automatic cutter. It can cut the briquettes automatically to the same length. This small device increases production efficiency a lot and improves the appearance of the biochar briquettes.

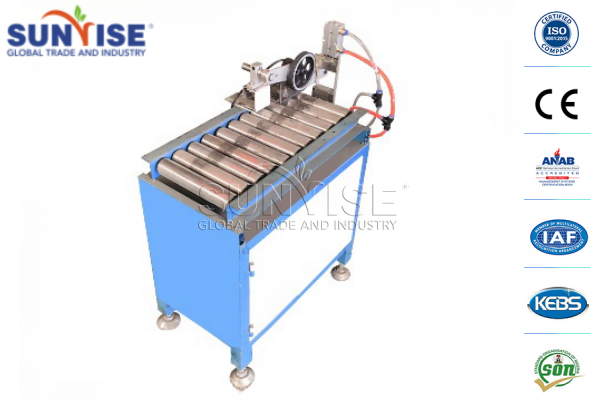

conveyor with rod charcoal briquette making machine

In addition to transporting materials, the conveyor belt also helps shape the charcoal sticks after producing. Because the biochar rods that have just been produced are very hot and soft overall. If you directly connect the packaging bag after making charcoal sticks, it will damage the integrity of the biochar sticks. For this, the function of the conveyor belt is to allow the newly produced biochar rods to be cooled and solidified using natural wind during transportation. This way you can greatly improve the quality of your final product.

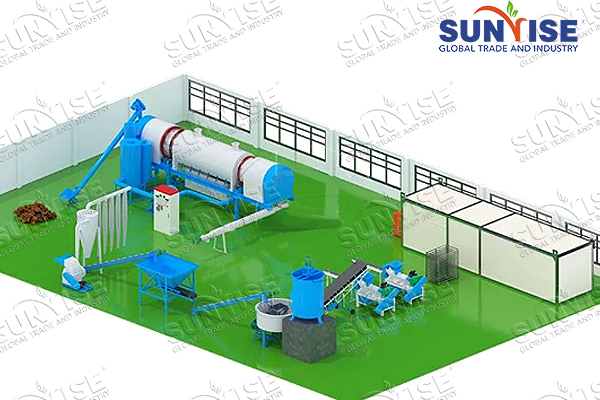

How to realize the continuous production of charcoal briquettes from biochar extruder?

As mentioned above, we provide the relevant introduction of the charcoal extrusion press as a stand-alone production. Then can it produce charcoal briquettes continuously? Of course. You can buy charcoal extruder machine and combing it with batching machine, crusher, mixer, carbonization furnace and packaging equipment. They will create a charcoal extruder briquettes production line, which ensures that you can deliver quality biochar briquettes to your customers continuously.

How about the final product made by the biochar extruder?

Through using different shapes molds, we can produce a variety of shapes of briquettes. And the die mold is easy to change and with long service life. So you can use just one machine to manufacture different briquette to meet your customers’ need.

What is the cost of charcoal brisket extruder machine plant?

The price usually plays as important role in charcoal brisket extruder machine plant selection. Then in terms of cost, our biochar extruding line can be divided into three parts:

Why do you invest in the charcoal briquettes production business with rod making machine?

The charcoal briquettes production business is popular because the industry is indeed profitable. The traditional lump charcoal production method has been gradually replaced by modern charcoal processing methods. After charcoal briquette extruding, they can be processed into various shapes and specifications, which makes charcoal briquettes more attractive in appearance and more versatile. In the process of processing charcoal briquettes, biochar briquettes processors also increase the added value of their products and thus obtain higher profits.

How to maintenance the charcoal extruder machine?

What are the different cutting method in charcoal extruder machine?

Why do you choose extrusion briquette maker rather than roller briquette press machine?

Extrusion briquette maker and roller briquette press machine are the most popular briquette machine in industry charcoal briquette making. So when should you choose the briquette extruder on building a big plant making charcoal briquette? The advantages of briquette extruder are as follow:

Factors affecting the forming of charcoal briquettes

In the production process of charcoal briquettes, there are some factors that will affect the molding effect of briquettes. And customers need to pay attention to them when using them.