If you plan to buy a charcoal grinder machine, cost is an item you must focus on. But, it is usually not fixed. The charcoal grinder equipment cost is closely related to the material types, capacity and equipment choosing, etc. As a professional char-molder equipment manufacturer, Sunrise designs charcoal grinding machine with different budgets for your choice. In addition, if you have any special requirements, we also can provide customized plan for your biochar grinder machine according to your requirements.

What is the cost of hammer mill for material processing?

When you prepare to dispose of branches, straw, wood shavings and corn stalks, etc, hammer mill is the best choice for you. There are two hammer mills according to the capacity for your choice. Small hammer mill and large hammer mill. Because of different capacity and type, they have different prices. You can choose one from them according to your needs.

Small hammer mill for sale

According to different driving methods, this hammer mill can be divided into electric type and diesel type. And it can process 100-2100 kg/h large material with the diameter around 30mm into smaller pieces with the diameter from 2mm to 5mm. Generally, the price of hammer mill is related to the capacity. So when you choose this machine, you only need $2,000-$15,000.

Large hammer mill price

If you want to grind 1-4 t/h materials, this equipment is the best choice for you. And it can increase pulverizing efficiency by 15%. So even with large grinding production, it does not affect work efficiency. In addition, it reduces a broad variety of friable and fibrous materials into very fine products in uniform size ranges from 20 to 300 mesh. For this, you need to prepare $5,000-$50,000 for it.

How much does mobile wood crusher for wood waste disposal cost?

If you want to start a wood processing production, there are two types of wood waste processing machine for your choice. Industrial wood chipper and mobile disc type tree stump shredder. They can grind different wood wastes. So what is the price of them?

Is there a low investment charcoal grinder machine for your choice?

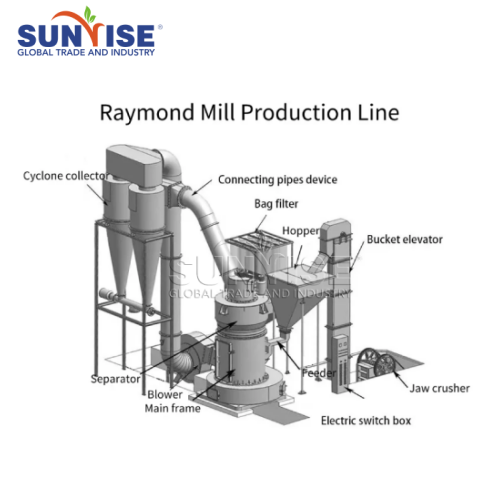

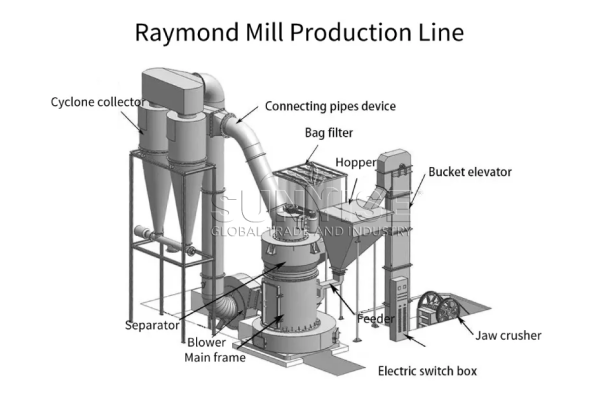

Of course. You can choose our charcoal wheel grinder and Raymond mill for charcoal crushing. For one thing, the former can use two or more rotating grinding wheels to grind charcoal into powder. And two rotating grinding wheel can also act as a mixer. When you put some binders with charcoal powder, this machine can mix them evenly. For another, the latter can not only crush charcoal, but also grind crushed materials into finer powder. So, for a dual-purpose charcoal grinder machine device, the price of charcoal wheel grinder is pretty cheap – $1,000-$5,000. Then the Raymond mill only needs $1,000-$7,000. But if you want to configure Raymond mill with dust removal system, the price will improve to $17,000-$25,000.

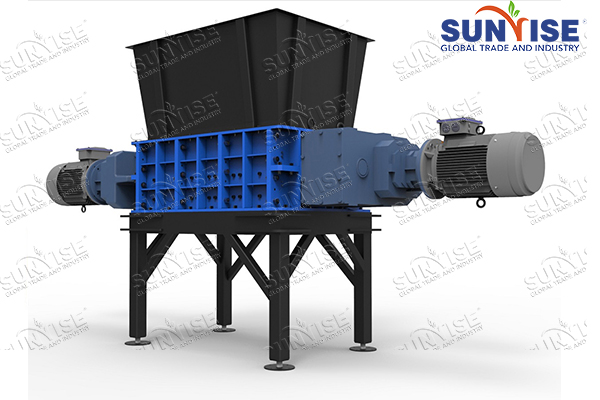

What is the price of double shafts shredder for solid waste processing?

Do you want to crush other solid waste materials, such as metal, tires polystyrene boxes, coconut shells, etc. It can break down the material with a high hardness easily because of stainless steel crushing blades and shaft design. So you only need $5,000-$50,000. Because it is divided into small and large double shafts shredder, this price range can be a reference for you. If you want to know the details, please contact us to get the specific quote!

Top 3 biochar grinding solutions price

When you prepare to crush charcoal, we can provide you with 3 solutions for your choice.

The above is the introduction about charcoal grinder machine price. If you want to know other machine price, we can also provide them for you. Such as charcoal briquette machine price, bamboo charcoal briquette plant cost, etc. Welcome to contact us immediately!