Flat die pellet machine is an ideal choice for small scale pellets production. When you want to produce wood pellets, feed pellets and charcoal granules, etc, this machine can meet your requirements. And it adopts dry granulation method, which mainly make use of the physical extrusion force between two or three rollers and pellet mill die to turn powder material into pellets. So it can produce quality granules with a suitable shape and size you need. What’s more, it only needs low investment and a short time.

How does the flat die pellet mill work?

Top 2 features in flat die pelleting machine

To determine whether this equipment is suitable for you, you need to know its features which can meet your requirements. Usually, the flat die pellet press has two characteristics as follows:

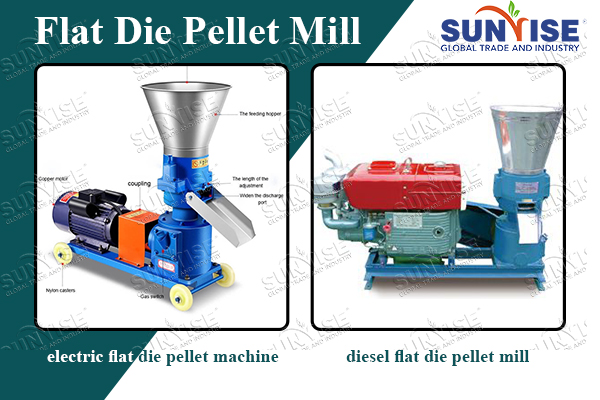

Electric and diesel engine

There are two engines for you choice in flat die pelleting machine-electric and diesel. Diesel flat die pellet mill is more suitable for pressing biofuel pellets in electric shortage area. And electric flat die pelleting machine is driven by electric motor which makes it more energy-saving and environmentally friendly. For this, you can select a suitable flat die pellet mill according to your local energy sources.

Feeding material size and moisture

When you prepare to make wood pellets, there are some requirements for raw materials. The size of materials is less than 5mm and the moisture of feeding materials need to get 14%-18%. If the size of these materials is not small enough, you can use crusher to grinding them. Only meeting the requirements of feeding materials size and moisture, you can produce high quality pellet.

What is the design of flat die pellet press?

Professional flat die pellet mill manufacturers are also focusing on the design of the machine’s components and structure. Excellent design of them plays a key role in the pellet production line. Therefore, if you want to buy flat die pelletizers to start your biomass pellet plant, you can ask the granulator supplier about the design of key components and structure to evaluate the performance of the pelletizer equipment.

How to set up a charcoal flat die granulation plant?

If you want to setup a charcoal flat die granulation plant, buying flat die pelletizer only is not enough, it is necessary to choose other charcoal processing machines to establish a professional charcoal granulation line. In this process, cost and factory area are two items you must pay attention to. So to establish a charcoal flat die granulation factory, you need to do the following things:

What equipment is needed in a charcoal flat die granulation line?

When you plan to create a charcoal granulation line, besides flat die granulator, you also need to buy feeding machine, crusher, mixer and belt conveyor. When it comes to make high quality charcoal pellets, you may also need to purchase a screening machine.

How much does a charcoal flat die granulation plant setup cost?

Cost also plays an important role in flat die granulation plant setup. It contains the costs of equipment, workshop building, energy consumption, worker employment, etc. Then because our flat die granulation system has characteristics of low energy consumption and high automation. And as a source factory of charcoal molder equipment, we can provide you with equipment at a favourable price. You can setup the flat die granulation plant at a low cost.

What is the area occupation of a charcoal flat die pellet making system?

The area occupation also will vary according to the capacity, layout and configuration. Generally, a 1-1.5 t/h charcoal flat die granulation line needs an area of 200-500㎡.