The hoist carbonization furnace adopts a hoisting combination structure and advanced hot air carbonization technology, which greatly improves the carbonization rate. So it is the ideal equipment for large and medium scale charcoal enterprises to produce charcoal.

Raw materials for carbonizing with vertical carbonization furnace

The hoisting charcoal furnace is suitable for large pieces of material, such as logs, wood chunks, wooden furniture trimmings, biomass briquettes, coconut shells, twigs, etc. So it is ideal for customers who want to obtain large pieces of charcoal. (If your raw material is less than 3cm, you can choose our continuous carbonization furnace.)

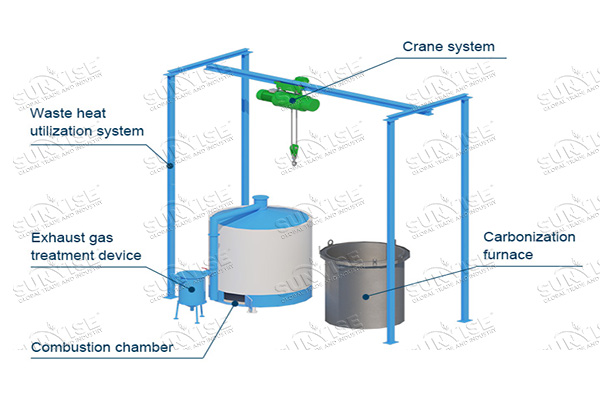

What is the design of hoisting carbonization furnace?

When you want to select a suitable carbonization furnace, the design of this machine is important. So the structure of the hoisting carbonization furnace mainly includes four parts: hoisting device, inner furnace, outer furnace, and gas circulation pipeline.

How does vertical carbonization furnace work to carbonize materials?

Firstly you need to put materials in the stove. But different materials adopt different ways to achieve. For wood sawdust briquette, you can put it in the steel basket, then use the hoist to put the steel basket into the inner stove. Then for woo log, wood branch, bamboo, etc, you need put them neatly in the basket, then put the basket into the inner stove. Finally, for coconut shell, nuts shell, etc, you should beat them into even part, then fix the small part in the basket and put the gasket into the inner stove.

After feeding materials, you can seal the stove for starting carbonization work. For wood briquettes, it will cost about 6 hours. And for other briquettes, they depend on the moisture and the material size. At this time, the temperature can get 600℃. As the wood burns in the furnace, it will produce combustible gases gradually. These gases are circulated and heated in the perforated ducts, eliminating the need for additional fuel when the fuel burns out.

Take the gasket by the hoist, put it somewhere to self-cool down. Then you need put another fixed gasket into the inner stove for another carbonization process.

After finishing the cool down process, you get the charcoal, take it out from the gasket! The waste gas generated during this process will be collected, which can help you maintain the production environment.

How to ensure if carbonization is complete?

You can observe the ducts in the combustion chamber. When the holes in the pipes are no longer on fire, the combustible gases have burned out and charring is complete.

4 features of vertical carbonization furnace in YS

How to realize the continuous production of charcoal with hoisting carbonizer?

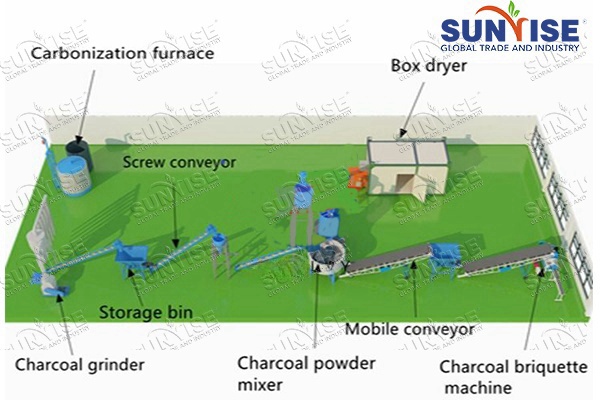

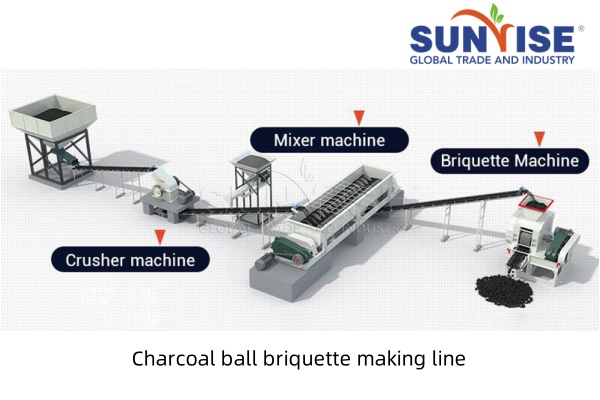

As mentioned above, a hoisting carbonization machine is suitable for small scale charcoal briquette making. Then can it produce biochar briquette in a large scale or continuously? Of course. You can buy multiple hoisting carbonization furnaces and combing them with crusher, mixer, briquette making machine and packaging equipment. They will create a charcoal briquette making line, which ensures that you can deliver quality charcoal to your customers continuously.

How to setup a hoisting carbonization plant?

If you want to setup a hoisting carbonization plant, buying hoisting carbonization furnace only is not enough. It is necessary to choose other charcoal processing machines to establish a professional charcoal briquette production line. In this process, cost and factory area are two items you must pay attention to. So to establish a hoisting carbonization plant, you need to do the following things.

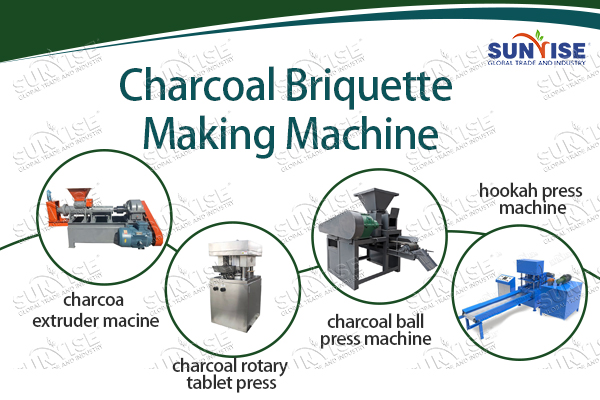

How to further process charcoal after hoisting carbonization?

If you want to make high quality charcoal briquette, there are also many other machines you can use to further process charcoal after carbonization. For example: