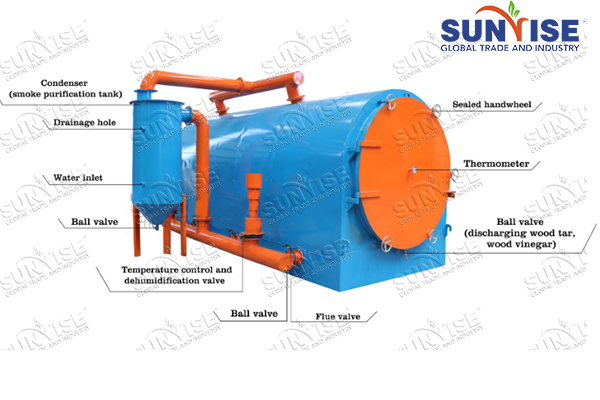

Horizontal carbonization furnace is a new type of charcoal making equipment. It adopts a horizontal design to reduce machine height. So it is more convenient for loading raw materials. Same as other airflow carbonization furnaces, it also includes a smoke recycle system. And smoke generated in the carbonizing process enters the purifier and then you can ignite it for heating the furnace. For this, it is very popular among charcoal processors.

3 Main structures of horizontal wood charcoal making machine

The horizontal charcoal making machine has a simple structure, including the three most important parts: thermal insulation rock wool, flue gas circulation pipe and trolley.

What other designs in horizontal carbonization furnace?

Besides the above introduction, its manufacturing process is very sophisticated and contains many components. Such as the gasification system, flue gas purification system, carbonization system, control system, combustion system, and power system.

What is the operating instructions of horizontal charcoal making machine?

- 1

First, you need find a flat piece of land and place the horizontal carbonizing machines.

- 2

Then, you can open the furnace door and put in the raw materials that need carbonization. Fill the furnace as much as possible.

- 3

In the next step, you can use wood to start the fire. When the temperature gauge in the hardwood charcoal furnace rises to 150-200 degrees, the horizontal log charcoal stove will discharge combustible gas. And gas will ignite spontaneously after passing through the pipeline.

- 4

After 5 hours of the carbonization process, the internal combustible gas is gradually used up. And the flame will become smaller and smaller at this time. At the same time as the fire is extinguished, completing the carbonization.

- 5

After that, you cannot open directly the carbonization furnace. Because the temperature of the carbonization raw materials in the furnace is too high and it is easy to ignite spontaneously and cause danger.

- 6

For this, you should use the furnace’s own spray system to properly pour some water, or wait until the temperature of the furnace surface drops below 50 degrees, then you can open the furnace door.

3 Temperature ranges in the carbonization process of horizontal carbonization machine

There are 3 temperature ranges when you use horizontal carbonization equipment. The following are the detailed information:

From the start of ignition, the furnace temperature rises to 160°C. At this time, the moisture contained in the machine-made rod mainly relies on external heating and the heat generated by its own combustion to evaporate. The chemical composition of the machine-made stick remains almost unchanged.

This stage mainly relies on the combustion of the rod itself to generate heat, causing the furnace temperature to rise to between 160 and 280°C. At this time, the wood material undergoes a thermal decomposition reaction and its composition begins to change. Among them, unstable components, such as hemicellulose, decompose to produce CO2, CO and a small amount of acetic acid and other substances.

The temperature at this stage is 300~650℃. During this stage, the wood material undergoes rapid thermal decomposition. At the same time, a large amount of liquid products such as acetic acid, methanol and wood tar are produced. In addition, producing flammable gases such as methane and ethylene. And these flammable gases are burned in the furnace. Thermal decomposition and gas combustion generate a large amount of heat, which increases the temperature of the furnace and makes the wood material carbonization into charcoal at high temperature.

How does raw materials affect the quality of horizontal carbonization?

The batch type carbonization furnace can carbonize raw materials such as waste branches, bamboo knots, bamboo tubes, fruit wood, oak, coconut shells, palm shells, etc. And the quality of charcoal is not only related to temperature, but also to the humidity of raw materials. Because, the humidity of the charcoal is too high, which will prolong the carbonization time on the one hand. On the other hand, when raw materials are pyrolyzed, they can produce large number of harmful substances. Therefore, the lower the raw materials humidity, the better the carbonization effect.

Why do so many manufacturers choose horizontal carbonization furnace?

By summarizing the past data of selling, we can find that this horizontal carbonization furnace is popular with charcoal suppliers. Why? Because it has many advantages which can attract biochar manufacturers to invest in as follows: