Do you want to make more profits from sawdust recycling? Are you looking for a project for making sawdust into high quality biochar briquette? Take action and turn sawdust into charcoal briquette! In this process, it is necessary to choose a suitable sawdust briquette charcoal making machine. In order to fully meet your requirements, YS not only design various sawdust char-molders for your choice, but also setup different sawdust biochar briquette making lines to help you finish sawdust biochar briquettes smoothly. Are they affordable for you? Of course as a leading char-molder equipment company, we will offer you sawdust charcoal briquette machines and business plans at a favourable price!

Top 3 sawdust briquette charcoal making machines for your choice

As a professional char-molder equipment supplier, we can provide you with various biochar briquette machines for sawdust processing. Among them, there are 3 types of sawdust char-molders that are popular with sawdust charcoal briquette manufacturers. They have different features and are suitable for different occasions, you can choose the right one according to your needs.

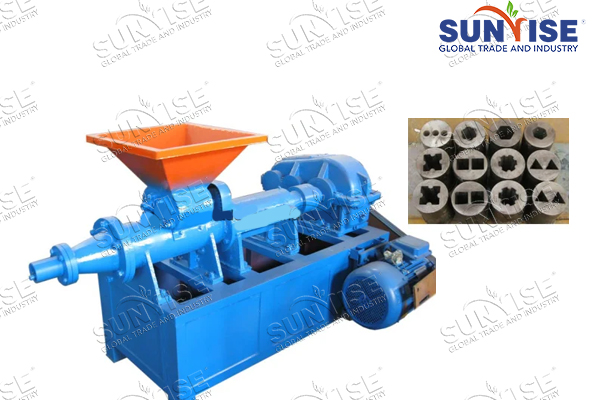

Charcoal extruder machine for small scale sawdust disposal

Our charcoal extruding machine can fully meet your requirements for the production of small scale sawdust biochar briquette making. If your sawdust generated less than 600 kg/h, we recommend you choose YS-140, which has a capacity of 400-600 kg/h. Moreover, we also can provide you with YS-180, which can help you produce 600-1000 kg/h of sawdust charcoal briquette.

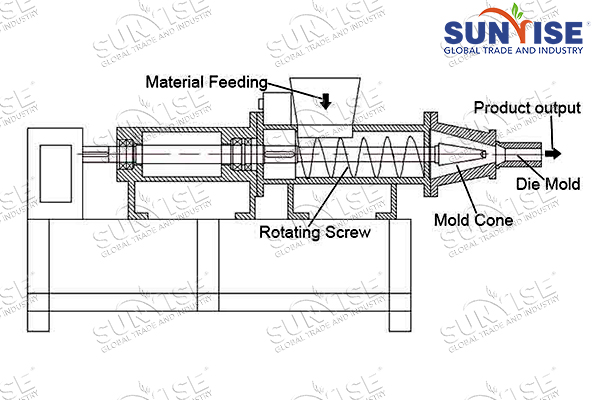

Because charcoal extruder machine adopts screw extrusion method, it can turn sawdust charcoal powder into briquette quickly. In this way, you can finish sawdust biochar briquette making in a simple process and it only needs a small area. So you can dispose of sawdust charcoal powder into briquettes in a small factory directly.

This machine can keep most characteristics of sawdust in your charcoal briquette. So that you can prepare sawdust biochar briquette which can be as biomass fuel for saving energy. In addition, it can meet your requirements of making sawdust biochar briquette of different sizes. We can offer you mold for 20-80 mm briquettes making.

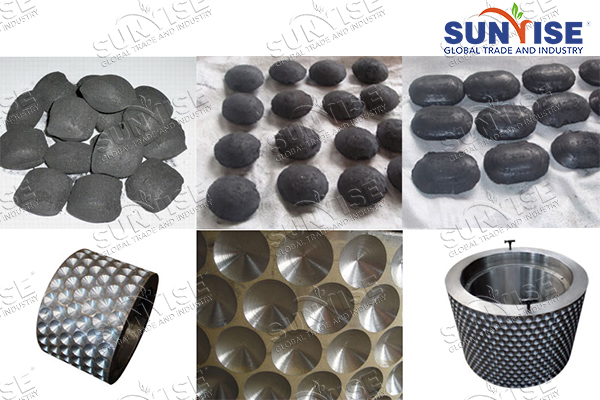

Charcoal ball press machine for large scale sawdust char-molder plant setup

Some charcoal briquette manufacturers want to invest in a large scale sawdust biochar briquette plant setup. For this, our roller briquette press machine is the most suitable one. There are two reasons:

Large capacity

The maximum capacity of it is 35 t/h. That is, only using one briquette equipment, you can produce 2-3 times more charcoal briquettes than other sawdust biochar briquette making machines. Meanwhile, its minimum model has an charcoal briquette output of 1-3 t/h.

Different the shape of final product

What briquette shapes can roller briquette press machine make? Including round, pillow, square and lath, etc. You only need to change the mold of this machine. And we can also customize the shape of final product from charcoal ball press machine according to your needs.

Hookah press machine for commercial sawdust charcoal briquette production

For those who produce sawdust charcoal briquette for commercial purposes and shisha charcoal briquette making, we recommend you choose our hookah press machine. Because it is beneficial for the following aspects:

How to establish a sawdust charcoal briquette production line?

To start commercial sawdust biochar briquettes making and sawdust char-molder plant setup more smoothly, it is necessary to establish a sawdust charcoal briquette production line. So besides charcoal briquette equipment, you may need the following sawdust processing machines.

3 Items you need to consider when setup a sawdust charcoal briquette plant

In general, when you plan to establish a sawdust charcoal briquette plant, you must consider the following 3 items:

For commercial sawdust biochar briquette making, suitable equipment choosing is important. In this way, you can prepare sawdust into the required charcoal briquette effectively and economically. Then what equipment is commonly used in sawdust biochar briquette production? Carbonization furnace, charcoal wheel grinder, blender, sawdust charcoal briquette making machine, dryer and packaging scale.

Besides machines buying, you also need to choose a suitable place to install them and start your sawdust charcoal briquette making. For one thing, it should be away from residential areas and easily accessible. For another, what’s more, it must be big enough to accommodate your sawdust biochar briquette production line. If you have a factory site, we can design a plant layout according to the details you tell us.

During sawdust charcoal briquette production plant setup, cost is an item you must focus on. But usually, it is not fixed and will change with capacity, equipment, design, etc. However, as a source factory, Sunrise will provide you with quality sawdust charcoal briquette machines at a favourable price. Even, we can off you sawdust charcoal briquette making plan according to your budget.

How many areas does sawdust charcoal briquette making line cover?

As mentioned above, besides equipment choosing, the factory area is also an item you need to pay attention to. Thus, how many areas does sawdust biochar briquette production line cover? Generally, you need to prepare a place of 100-150㎡ for a 500-1000 kg/h sawdust charcoal briquette making line installation. How about a 1-10 t/h sawdust charcoal briquette system? It is about 500-1,000㎡. And when you want to setup a large scale sawdust charcoal briquette factory with 10-30 t/h, it needs 1000-5000㎡. In addition, if your factory space is smaller, you can contact us for customized sawdust biochar briquette production plant design.

What is the cost of your sawdust charcoal briquette manufacturing line?

The price usually plays an important role in sawdust charcoal briquette manufacturing line. Then in terms of cost, our sawdust charcoal briquette making system can be divided into three parts:

Making higher profit from sawdust charcoal briquette machine

Speaking of making profit from sawdust charcoal briquette machine, the investors care the returns most, which is the base of investment. Everything is empty talk if there is no returns. So how much returns can get when producing one ton of charcoal briquette?

The first thing you should consider is the cost of raw materials before using the sawdust charcoal briquette machine to making charcoal briquettes. Generally, 2.5 tons of raw materials mixed with sawdust and rice husk in the moisture of 30% can be made into 1 ton of charcoal after drying to moisture of 5%-12%. And the raw materials cost different in different places, there exists some places where the raw materials cost free almost; while in other places, the raw materials cost very high. Thus, the raw material cost is the key of making sawdust charcoal briquettes.

Commonly, sawdust and rice husk cost $11-41 per ton. Putting the sawdust and rice husk as an example, let’s calculate the profit when producing one ton of charcoal briquettes (one ton of mechanical charcoal needs 2.5 tons of raw materials):

|

Cost factors |

Unit price ($) | Unit | Total price($) |

|---|---|---|---|

| Raw materials

(sawdust, rice husk) |

41 | 2.5 tons |

103 |

| Electricity consumption | 0.13 | 190 degrees |

26 |

|

Operator |

11 | 3 persons |

33 |

| Total |

162 |

In a word, about that if the profit is considerable or not, you can also make a cost list according to the local actual situation and then decide to invest it when you see profits.

Why do you choose sawdust as material to make charcoal briquette?

The main body of the wood is made up of cellulose, hemicellulose and lignin. The cellulose gives the wood mechanical strength and toughness, lignin is bonding fibers inside the plant, and hemicellulose is a bridge to connect the cellulose and lignin together. When the sawdust is making, the briquette pressure (or may also involve to other heating systems) causes the raw material’s temperature rise. The lignin becomes soft and has the ability to bind the sawdust together. Sawdust has a lignin content bigger than other biomass materials, and with less ash content, thus made the briquette with higher quality.

| Material | Lignin | Cellulose | Hemicellulose | Ash content |

|---|---|---|---|---|

| Wood sawdust (%) | 20 | 39 | 34 | 0.3 |

| Wheat straw (%) | 17 | 40 | 28 | 3 |

| Rice straw (%) | 12 | 32 | 25 | 13 |